Hitting the 3D printing and modelmaking sweet spot

In the realm of model making, a perfect sweet spot sits where the techniques of traditional model making, laser cutting, and 3D printing converge to create a beautiful model-making experience.

This integration not only enhances the speed of production but also significantly improves cost-effectiveness by reducing material waste and labor time. Furthermore, the precision offered by laser cutting ensures clean and intricate designs, while 3D printing allows for complex shapes and fine details that would be difficult to achieve through conventional methods.

Together, these technologies elevate the overall quality of the final product, resulting in models that exhibit exceptional detail and accuracy.

For years, those of us within the 3D printing UK community have believed that 3D printing could eventually replace traditional model making. However, we have come to understand that both practices are not only distinct but also highly complementary.

While traditional model making does not rely on 3D printing, the integration of this technology significantly enhances the overall workflow. 3D printing enables the rapid production of highly detailed components with intricate geometries and complex curves that would be difficult or impossible to achieve through conventional methods.

This capability allows model makers to focus on the artistic aspects of their craft, such as refining surface textures, applying paint finishes, and perfecting details by hand. With skilled artisans working alongside advanced printing technology, the final models benefit from both precision engineering and expert craftsmanship, resulting in an impressive combination of functionality and aesthetic appeal.

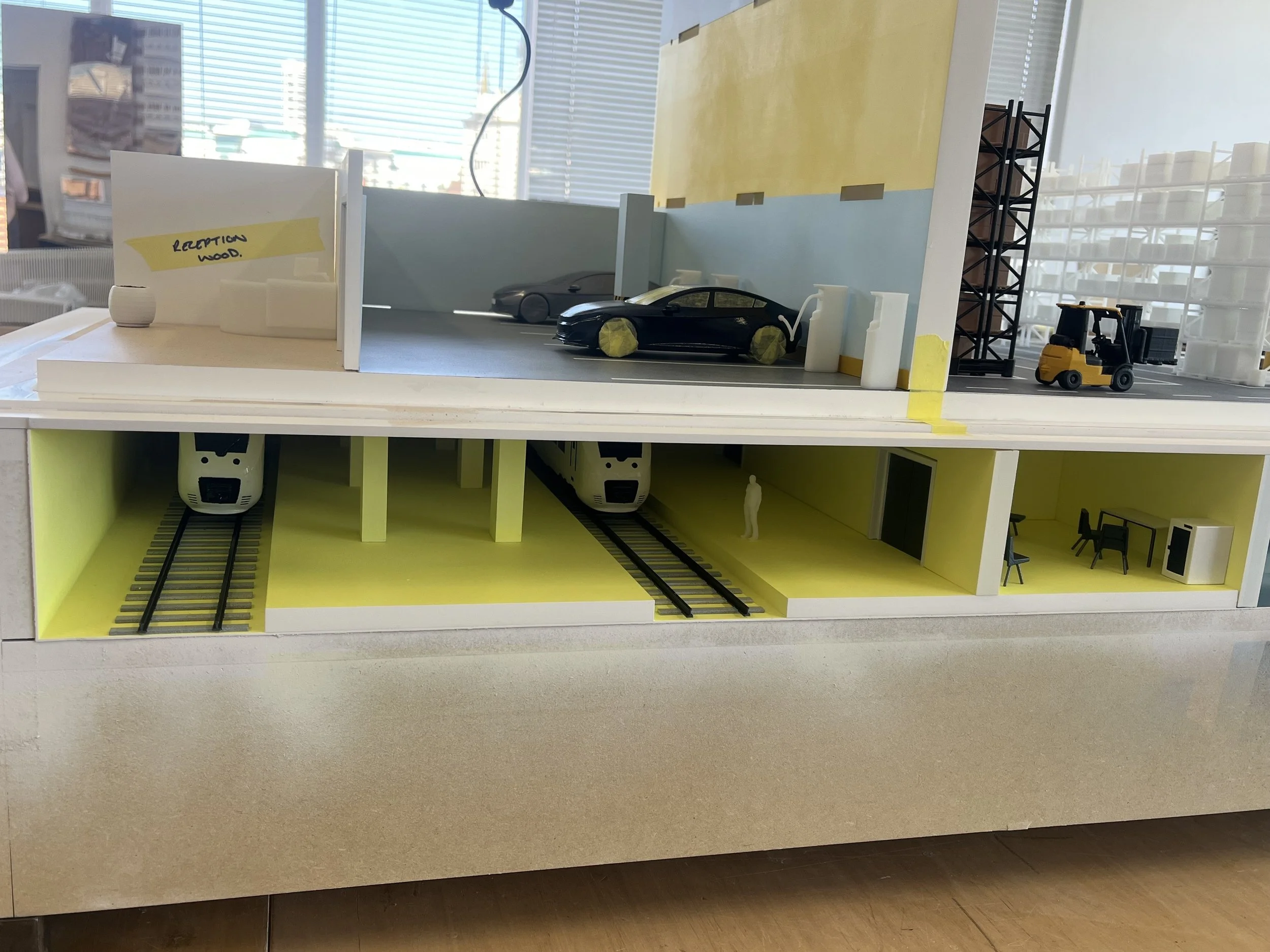

Here is an impressive example of a project we developed in collaboration with Kingel Ltd, a leading creative brand and campaign specialist, for Legrand, renowned experts in digital solutions and infrastructure development.

This project features intricate animation created using highly detailed laser technology stereolithography 3D printing. The physical structure was expertly handcrafted, incorporating high-quality materials, and was enhanced with a professional spray painting technique for a vibrant finish. Additionally, custom laser-cut glazing was incorporated to add depth and dimension, ensuring the final product was both visually striking and functional.

At Fixie, we specialise in 3D printing and understand model making, so we can combine our expertise to find the best possible method for your project. Our team understands the intricacies of breaking down models into optimal components, ensuring that each part is designed for maximum strength, detail, and ease of assembly.