The Best Approach: 3D Printing and Traditional Model Making

Why hybrid 3D printing and traditional model making work

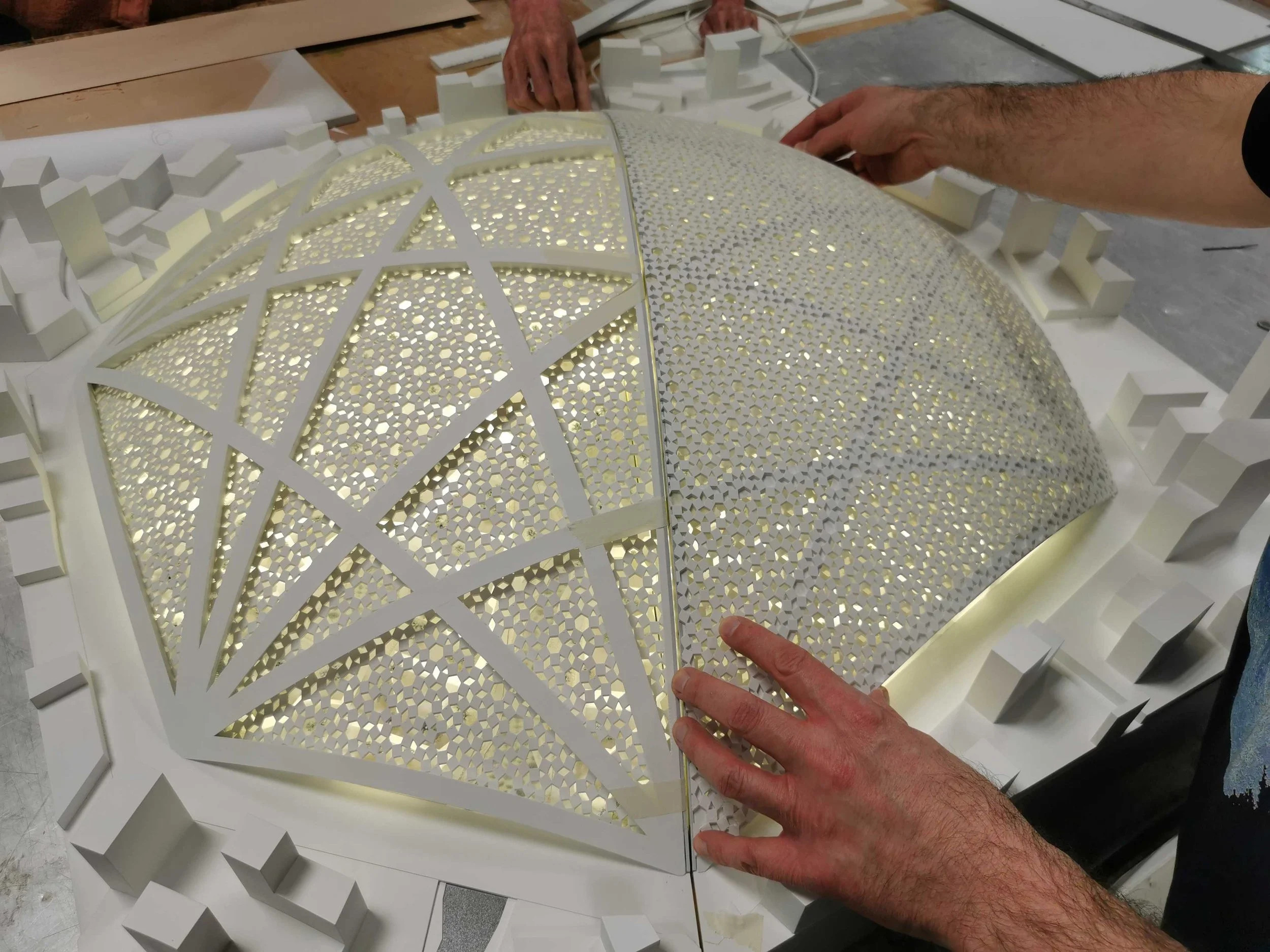

Architectural presentations demand models that are both accurate and attractive. Combining 3D printing and traditional model making meets this need by merging digital precision with human artistry. Modern additive manufacturing creates complex geometries that are difficult to craft by hand, while traditional modelmaking techniques bring warmth, texture and creative detailing to every piece

Advantages of 3D printing: precision, complex geometry, speed

Stereolithography (SLA) 3D printing UK offers the sharpest details and smoothest surface finish of all 3D technologies. Using a UV laser to cure liquid resin, SLA captures features as fine as 25 microns, ideal for architectural models requiring crisp edges and thin walls. This resin printer workflow allows rapid prototyping of curved façades, intricate lattice structures and free-form shapes, all directly from STL files.

Advantages of traditional craftsmanship: texture, finish, realism

Once printed, models benefit from hand finishing techniques such as sanding, spray painting, and assembly of multiple parts. Skilled model makers apply model finishing techniques to smooth seams, add textures, and enhance realism. Traditional tools like scalpels, rulers, and airbrushes bring a bespoke quality that machines alone cannot replicate

Typical workflow at Fixie 3D

Fixie 3D integrates 3D printing and traditional model making into a seamless service, tailored for London-based architects and designers.

Step 1: File Preparation and Consultation

Clients upload 3D model files (STL, OBJ or FBX) via our secure portal. Our technicians review the design, recommend the best 3D printing services and advise on resin types for durability or translucency

Step 2: SLA Printing at Scale

We print on large-format SLA machines (750 × 750 × 550 mm) capable of high-resolution output and multi-piece assemblies. This additive manufacturing stage captures complex details—from fine window mullions to organic façade elements—with exceptional accuracy

Step 3: Hand Assembly and Finishing

Our 3d modelmakers then remove support structures, sand surfaces, and apply spray paint to match project palettes. They also glue parts together and may incorporate CNC-cut wooden bases for a refined mixed-media effect.

Step 4: Quality Control and Delivery

Every model undergoes a final inspection for tolerances, paint consistency and structural stabilityWe then package the model securely for prompt delivery anywhere in the UK or internationally

Benefits for architects, designers, and model clients

By automating complex sections through 3D printing uk, we cut manual labour time and reduce errors, leading to faster prototype development and lower costs per unit. Architects can iterate designs quickly, testing form and scale without lengthy hand-crafting phases

Enhanced Visual Impact

The combination of digital precision and expert hand finishing creates models that stand out in client presentations and competitions Crisp resin prints capture every curve, while bespoke paintwork and textures evoke material qualities such as brick, timber or metal Scalability and Flexibility

From small concept models to large format competition entries, our hybrid workflow adapts to any project size Clients benefit from modular assembly and the ability to update individual components without reprinting an entire model.

Q: Why combine 3D printing and traditional model making?

A: Combining 3D printing’s precision with traditional craftsmanship’s finishing delivers highly detailed, realistic models efficiently.

Q: What 3D file formats are accepted for hybrid model making?

A: STL, OBJ, and FBX are typically accepted for the 3D printing stage. Fixie - Architects' AssistantQ: What is the maximum build size for large-format printing at Fixie 3D?

A: Fixie 3D’s large-format SLA build volume is 750 × 750 × 550 mm. Fixie - Architects' AssistantQ: What types of finishing can be done after printing?

A: Post-processing can include support removal, sanding, spray-painting, assembly, and mounting on CNC-cut bases for mixed-media effect. Fixie - Architects' AssistantQ: When might a pure traditional model or pure 3D print be preferable?

A: Pure traditional suits simple geometries needing texture/material realism; pure 3D print suits rapid prototyping with minimal finishing — hybrid suits most detailed architectural models.

Conclusion

The best approach truly combines 3D printing and traditional model making. At Fixie 3D in London, our SLA technology delivers the finest details and complex curves, while our model makers apply their creativity to handcraft the rest. This synergy accelerates prototype development, enhances visual impact, and offers a cost-effective, scalable solution for architects and designers.