Introduction: The Foundation of Every Architectural Print

When it comes to architectural model making, precision and presentation are everything.

Whether you’re producing a conceptual massing model or a high-detail BIM-based prototype, the fabrication approach you choose will directly impact the accuracy, surface finish, and overall quality of the final model.

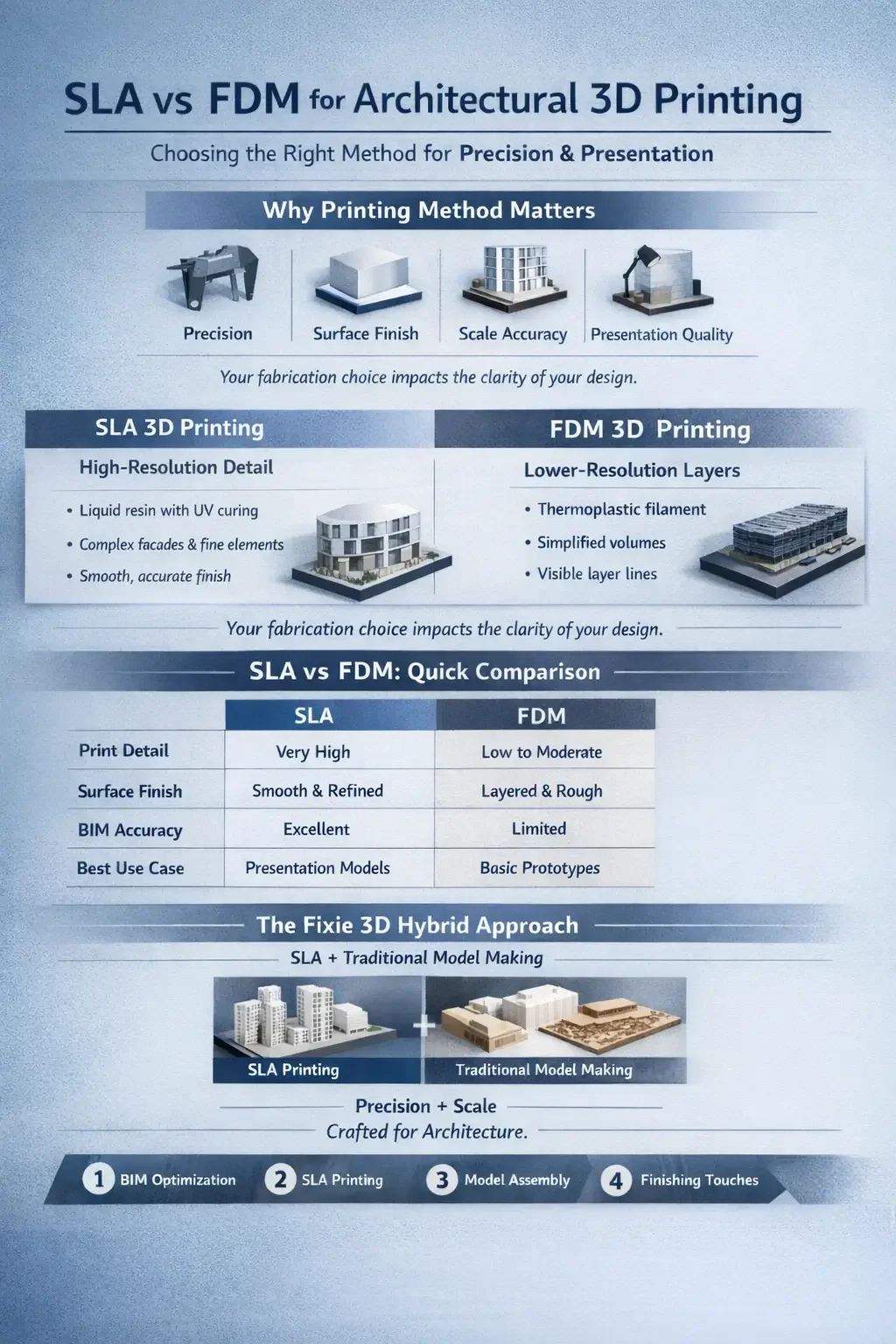

While SLA and FDM are often discussed together in architectural 3D printing, it’s important to understand how these technologies are referenced within professional model making workflows — and how traditional model making techniques are used alongside high-resolution printing.

At Fixie 3D, we specialise in combining SLA 3D printing with traditional architectural model making to deliver scalable, presentation-quality models without compromising detail or finish.

Understanding the Two Technologies

Before comparing approaches, it’s essential to understand how these two methods work.

SLA (Stereolithography)

SLA uses liquid resin cured by a UV laser to build highly detailed models layer by layer. It is known for smooth surfaces, fine resolution, and excellent accuracy.

At Fixie 3D, SLA printing is used for complex facades, interior elements, and scaled architectural components derived directly from BIM data.

FDM (Fused Deposition Modeling)

FDM extrudes thermoplastic filament layer by layer to form solid objects. While it is often referenced in discussions around rapid or simplified prototyping, it typically produces visible layer lines and lower surface resolution.

For professional architectural presentation models, surface quality and fine detail are critical considerations.

SLA 3D Printing for Architecture: Advantages and Limitations

Advantages

Unmatched Detail and Precision

SLA reproduces fine architectural geometries accurately, making it suitable for intricate facades, window systems, and small-scale components.Smooth Surface Finish

SLA produces clean, refined surfaces that require minimal post-processing, supporting high-quality presentations.Material Versatility

Resin materials allow for translucent and solid elements, helping visually differentiate components within a model.BIM-to-Physical Accuracy

When printing directly from Revit, Rhino, or Archicad models, SLA preserves subtle design intent.

Limitations

Higher Cost per Printed Volume

SLA materials and post-curing processes require careful and efficient use.Smaller Build Volumes

High-resolution SLA printers are best suited to detailed components rather than large single-piece structures.Longer Production Time

Print times increase as detail and accuracy increase.

These considerations are addressed through a hybrid model making workflow.

FDM in Architectural Model Discussions: Advantages and Limitations

Commonly Referenced Advantages

Production of simplified volumes

Ability to print larger single parts at lower resolution

Limitations for Architectural Presentation Models

Lower resolution and reduced detail

Visible layer lines requiring extensive finishing

Limited material aesthetics for display-quality models

For these reasons, Fixie 3D does not use FDM printing for architectural presentation models.

SLA vs FDM: Which Is Right for Your Project?

Rather than relying on a single printing method, architectural models benefit from selecting the most appropriate fabrication approach for each component. At Fixie 3D, SLA is the core 3D printing technology, supported by traditional architectural model making to achieve presentation-quality results.

Print Detail

SLA (Stereolithography): Delivers extremely high detail, making it ideal for architectural presentation models and intricate design elements.

FDM (Fused Deposition Modeling): Produces low to moderate detail and is not suitable for fine architectural features.

Surface Finish

SLA: Produces smooth, refined surfaces that require minimal finishing.

FDM: Creates visible layer lines and typically requires extensive post-processing to improve appearance.

Material Options

SLA: Uses resin-based materials that can be translucent or rigid, allowing clear visual differentiation within architectural models.

FDM: Uses thermoplastic filaments, which are functional but limited in visual refinement.

Durability

SLA: Best suited for display and presentation models where visual quality is critical.

FDM: Structurally robust but visually limited for professional presentation use.

Build Volume

SLA: Optimised for smaller components where high detail and precision are required.

FDM: Capable of producing larger single-piece prints, often at lower resolution.

Best Use Case

SLA: Detailed architectural elements and presentation-quality models derived from BIM data.

FDM: Simplified prototyping and early-stage design discussions.

Combining Both: The Fixie 3D Hybrid Approach

Many architectural models require both precision and scalability.

Instead of combining multiple printing technologies, Fixie 3D uses a hybrid approach that combines SLA 3D printing with traditional architectural model making techniques.

For example:

SLA printing is used for detailed facades, windows, and architectural features

Traditional model making is used for bases, terrain, massing, and structural components

This approach balances detail, scale, and presentation quality.

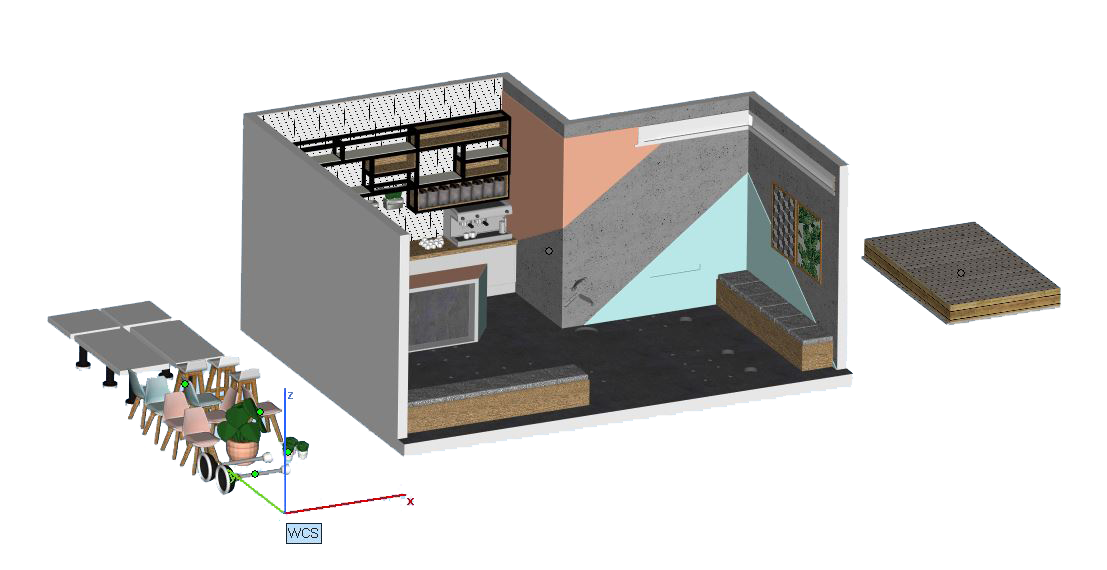

Practical Example: Printing from BIM Models

At Fixie 3D, we frequently work with Revit and Archicad files that require optimisation for physical production.

Our workflow typically includes:

Geometry cleanup and export

Detail segmentation for SLA printing and traditional fabrication

Scaling and assembly planning

Post-processing and finishing

This ensures accuracy, efficiency, and professional presentation standards.

Environmental and Sustainability Considerations

Using SLA selectively for detailed components and traditional model making for volume reduces material waste and unnecessary printing.

Fixie 3D prioritises efficient workflows that support both quality outcomes and responsible production.

Conclusion: Choosing with Purpose

Architectural models should clearly communicate design intent.

Rather than relying on lower-resolution printing methods, a hybrid approach led by high-resolution SLA printing and traditional model making delivers the best balance of detail, scale, and visual quality.

At Fixie 3D, we help architects translate BIM models into refined physical models using the right method for every element.

Ready to print your design?

Transform your BIM model into a high-detail architectural model with Fixie 3D. Upload your design and our team will guide you through the best approach for your project.

3D architectural models have become essential tools for architects, designers, builders, and property developers. Whether you're designing a home renovation, planning a large commercial space, or presenting to investors, 3D models help transform abstract ideas into realistic, visually compelling representations.

In this guide, we break down everything you need to know—from what 3D architectural models are to how much they cost, the types available, and why they’ve become indispensable in modern design workflows.

What Is a 3D Architectural Model?

A 3D architectural model is a digital or physical representation of a building, interior, landscape, or structural concept. These models simulate real-world dimensions, materials, textures, lighting, and spatial relationships, allowing stakeholders to visualize a project long before construction begins.

Modern 3D models go far beyond simple drawings. They offer clarity, realism, and interactivity—helping teams catch design issues earlier and make smarter decisions.

Why Use a 3D Architectural Model for Your Project?

3D modeling enhances every stage of a project, from design to approval to construction. Some of the top benefits include:

Realistic visualization: See exactly how your property or space will look before building starts.

Early issue detection: Spot structural or design inconsistencies before they become costly mistakes.

Better communication: Architects, clients, builders, and investors can all understand the design clearly.

Faster decision-making: Accelerates approvals and cuts down on lengthy revision cycles.

Because search engines now reward content that answers real user intent rather than listing keywords, explaining these benefits in natural, meaningful language strengthens the semantic relevance of this page, improving SEO performance .

Types of 3D Architectural Models

Studios typically offer a range of models depending on the project’s goals:

1. 3D Exterior Models

Showcase building facades, materials, landscaping, lighting, and street-level views.

2. 3D Interior Models

Ideal for interior designers and homeowners. These models include furnishings, décor, textures, and lighting scenarios.

3. Floor Plan Models

A simplified top-down view showing room layouts, furniture placements, and circulation paths.

4. Landscape & Site Models

Great for developers and urban planners; these models visualize outdoor spaces, terrain, pathways, pools, gardens, and civic layouts.

5. 3D Walkthrough Animations

Interactive or video-based walkthroughs that allow viewers to “move through” the space—excellent for marketing and pre-sale campaigns.

6. Physical Scale Models

Produced through 3D printing or handcrafting, these tangible models are often used in exhibitions and presentations.

What File Formats Do Designers Accept?

Most 3D modeling professionals accept a wide range of file formats, including:

CAD files (DWG, DXF)

SketchUp (SKP)

Revit (RVT)

3ds Max (MAX)

PDF drawings

Hand-drawn sketches (as long as measurements are provided)

Accepting diverse file types helps maintain momentum in projects, which aligns with modern semantic search behavior—users often ask about compatibility, workflows, and practical execution, not just the definition of 3D modeling.

How Long Does It Take to Create a 3D Architectural Model?

Project timelines vary depending on model complexity, level of detail, and revisions required. Common turnaround times include:

Small interior or exterior model: 2–4 days

Full building model: 5–10 days

Large commercial development: 2–4 weeks

These timeframes help set realistic expectations for clients and ensure smoother planning during construction phases.

How Much Do 3D Architectural Models Cost?

Pricing depends on complexity, detail level, materials, realism, and number of revisions. Typical ranges:

Basic models: $150–$300

High-detail residential/commercial models: $800–$3,000+

Providing clear cost ranges improves transparency—a key characteristic of helpful content under Google’s Helpful Content and MUM frameworks.

* Contact us for pricing and timelines of delivey

Can a 3D Model Be Created from Old Drawings or Hand Sketches?

Yes. Even older blueprints or scanned hand-drawn sketches can be converted into detailed 3D architectural models, as long as measurements are provided. This is especially useful for renovations and historical preservation projects.

Are Revisions Allowed?

Most studios offer 1–3 free revisions, with additional revisions available for a fee depending on the scope of changes. This ensures accurate alignment with project goals without derailing timelines.

Do You Provide Photorealistic 3D Rendering?

Absolutely. Many 3D artists deliver HD or 4K photorealistic renderings that include realistic lighting, shadows, textures, materials, and environmental effects. These visuals are commonly used for:

Real estate listings

Investor presentations

Marketing campaigns

Pre-sale brochures

Well-rendered content aligns with user expectations for vivid, realistic previews.

Can I Get Animation or Walkthrough Videos?

Yes—walkthroughs, flythroughs, and 360° virtual tours can be generated from your completed 3D model. These immersive experiences are powerful tools for sales and client engagement.

Industries That Rely on 3D Architectural Models

3D modeling supports a wide range of sectors, including:

Real estate

Construction

Interior design

Landscaping

Hospitality design

Retail & commercial architecture

Urban planning

Because semantic search understands topic relationships, covering multiple industries broadens contextual relevance without keyword stuffing.

Is 3D Printing Available?

Many studios now offer 3D-printed architectural models using materials like PLA, resin, or architectural-grade plastics. These physical models help stakeholders grasp scale and spatial relationships more intuitively.

Final Thoughts

3D architectural models continue to reshape the design and construction landscape. They help clients visualize concepts with clarity, enable teams to avoid costly mistakes, and support more informed decision-making throughout the entire project lifecycle.

Introduction: The Convergence of Technology and Design

Architecture has always balanced imagination with engineering precision. From Gothic cathedrals to Bauhaus modernism, every era has been defined by its materials and methods. Today, 3D printing—also known as additive manufacturing—is emerging as the next revolutionary force, reshaping how we design, prototype, and construct buildings. What began as a tool for rapid prototyping is now being applied to full-scale architectural structures, signaling a fundamental shift in how we conceptualize and realize the built environment.

This transformation is not just about new tools but about redefining the creative and structural boundaries of architecture. 3D printing introduces digital precision, material efficiency, and design freedom, enabling architects to translate complex geometries into tangible reality faster and more sustainably than traditional construction methods.

The Evolution of 3D Printing in Architecture

From Concept Models to Construction Components

In its early stages, 3D printing was primarily used for architectural modeling—creating miniature prototypes that helped clients visualize designs. This application reduced manual model-making time and enhanced presentation accuracy. However, the technology quickly advanced beyond small-scale prototyping.

With industrial-grade printers capable of extruding materials such as concrete, clay, polymer composites, and even bio-based substances, 3D printing evolved into a tool for fabricating building components—and eventually entire structures.

Key Milestones

2014 – Winsun (China): One of the first companies to 3D-print full-sized concrete houses using a custom-built printer.

2016 – Office of the Future (Dubai): The world’s first 3D-printed office building, demonstrating the scalability of the technology.

2021 – ICON & NASA Collaboration: Using lunar regolith simulations to 3D-print structures that could support extraterrestrial habitats.

Each of these milestones reflects a growing confidence in 3D printing as a viable construction technology rather than a novelty.

How 3D Printing Works in Architecture

The Additive Manufacturing Process

Unlike subtractive methods that cut or mold materials, additive manufacturing builds layer by layer from a digital model (CAD file). In architectural applications, this process typically involves:

Digital Design & Simulation – The structure is modeled using parametric design software like Rhino or Grasshopper.

Material Preparation – Specialized mixtures such as printable concrete, geopolymers, or bioplastics are developed for extrusion.

Printing Execution – A robotic arm or gantry system deposits material precisely as per the digital model.

Curing & Post-Processing – Layers solidify or cure, often reinforced with rebar, insulation, or finishing treatments.

The result: structural components or even entire walls produced with millimeter-level accuracy.

The Advantages of 3D Printing in Architecture

1. Design Freedom

Traditional construction imposes limitations due to formwork and manual labor constraints. 3D printing removes these barriers, enabling organic, parametric, and biomimetic designs. Curves, lattice structures, and adaptive facades can be fabricated without additional cost or complexity.

2. Material Efficiency

Because materials are deposited only where needed, waste is dramatically reduced—a critical advancement in sustainable construction. Many architectural firms now experiment with locally sourced and recyclable materials, aligning with circular economy principles.

3. Speed and Cost Reduction

3D-printed structures can be erected in days rather than weeks, reducing labor costs and on-site risks. For instance, ICON’s 3D-printed homes in Texas can be completed in under 48 hours.

4. Sustainability and Carbon Reduction

By optimizing material use and reducing transportation needs, 3D printing directly contributes to lower embodied carbon. Moreover, bio-based materials such as mycelium composites or recycled polymers are gaining traction for eco-friendly architecture.

5. Customization and Scalability

Mass customization—once an oxymoron—is now achievable. With 3D printing, architects can personalize designs for specific environments, climates, or user needs without inflating costs.

Materials in 3D-Printed Architecture

Concrete-Based Materials

The most common medium for large-scale architectural 3D printing is cementitious composite. Formulated to flow easily yet retain structural integrity upon extrusion, it combines traditional concrete with additives like silica fume and fly ash for enhanced performance.

Polymers and Composites

For lightweight structures or façade elements, thermoplastic polymers (PLA, ABS, PETG) and fiber-reinforced composites are increasingly used. They allow high-resolution detailing and light-transmitting geometries.

Natural and Bio-Based Materials

Researchers are exploring clay, soil, hempcrete, and biopolymer blends for environmentally responsible construction. Such materials reduce reliance on high-carbon cement while improving thermal properties.

Iconic 3D-Printed Architectural Projects

1. The Office of the Future – Dubai

A 250-square-meter office printed in 17 days, demonstrating the scalability of concrete 3D printing. It used a 6-meter-tall printer and reduced construction waste by over 60%.

2. TECLA House – Italy

Designed by Mario Cucinella Architects, TECLA is made entirely from local clay, symbolizing the union of vernacular materiality and digital craftsmanship. It is fully recyclable and energy-efficient.

3. Project Milestone – Netherlands

Europe’s first 3D-printed residential community, where each house showcases unique geometries produced using parametric algorithms.

4. ICON’s House Zero – USA

Combining robotics, AI-driven design, and 3D printing, ICON built a high-performance home integrating passive cooling and low-carbon materials—a model for future housing.

The Role of Digital Design and AI in 3D Printing Architecture

3D printing in architecture thrives on the integration of parametric modeling, machine learning, and AI-driven optimization. These technologies enable architects to:

Analyze structural behavior before printing

Optimize material distribution for minimal waste

Simulate environmental performance (daylight, airflow, temperature)

Generate adaptive forms based on site-specific data

By merging data intelligence with fabrication, architects are evolving into computational designers—a discipline where form, function, and fabrication are algorithmically linked.

Challenges and Limitations

While 3D printing offers transformative potential, several challenges remain:

1. Regulatory Hurdles

Building codes and zoning regulations have not yet fully adapted to 3D-printed construction. Certification processes lag behind technological capabilities.

2. Material Constraints

Current printable materials are limited in tensile strength and thermal performance, requiring hybrid reinforcement methods.

3. Scalability and Cost of Equipment

Industrial printers are expensive and require significant power, making them inaccessible for smaller architectural firms.

4. Workforce Training

Transitioning from manual labor to digitally controlled fabrication requires reskilling architects, engineers, and contractors.

Sustainability and the Circular Future of Architecture

3D printing aligns strongly with sustainable architecture principles, including:

Resource efficiency through precise material deposition

Reduced waste streams

Local production minimizes transportation emissions

Recyclability and modularity for adaptable reuse

Emerging research focuses on closed-loop material systems, where printed components can be ground, remixed, and reprinted, creating circular construction cycles. When combined with renewable energy and low-carbon binders, this could redefine architecture’s relationship with the environment.

The Social Impact of 3D-Printed Construction

Beyond aesthetics and technology, 3D printing has profound social implications. Affordable housing projects in regions like Latin America, Africa, and Asia use 3D printing to combat housing shortages.

Organizations like New Story and ICON have already built communities using low-cost 3D-printed homes designed to withstand local environmental conditions. These projects illustrate how additive manufacturing can bridge technological innovation and social equity—creating sustainable shelter at scale.

The Future: From Earth to Mars

The architectural applications of 3D printing are not limited to Earth. NASA and ESA are actively researching in-situ resource utilization (ISRU)—using local materials like lunar or Martian soil to 3D-print habitats for space exploration. This futuristic vision reflects a profound truth: additive manufacturing could become the universal language of construction, adaptable to any environment, planet, or material.

Conclusion: Printing the Next Chapter of Architecture

3D printing represents more than a new construction method—it’s a new philosophy of making. It challenges traditional hierarchies between design, fabrication, and sustainability, allowing architects to prototype ideas directly into built form.

As material science, robotics, and AI converge, the dream of digitally crafted, ecologically responsible architecture is rapidly becoming a reality. Whether printing a Mars habitat or a local home, the goal remains the same: to build smarter, faster, and more harmoniously with our planet.

Architectural site models are powerful tools for effective communication. They help planning officers, investors, and communities tangibly visualize projects. But creating them comes with a cost—both financial and environmental.

Traditionally, site models have been carved from foam boards or dense model-making sheets using CNC routers. More recently, additive methods like large-format SLA (stereolithography) 3D printing have become a viable alternative. Both approaches deliver the scale and presence architects need, but they differ dramatically in how they use (and waste) materials.

This article explores the sustainability case for each method, focusing on waste reduction, energy use, transport, and reusability. The aim isn’t to declare one approach “better,” but to help practices choose the method—or combination—that aligns with their sustainability goals.

Why Waste Matters in Architectural Model-Making

Before diving into processes, it’s worth asking why waste deserves attention in the first place.

Volume of material: Site models, especially urban masterplans and campus layouts, cover wide areas. They require substantial baseboards, terrain, and massing. That means a lot of input material before you even start adding detail.

Short lifespans: Many models are created for competitions, exhibitions, or planning submissions. After their purpose is served, they’re often dismantled or discarded.

Hidden costs: Waste doesn’t just sit in a bin. It carries embodied carbon from extraction, processing, and transport. Foam offcuts and dust also present recycling challenges, while resin and solvent waste needs careful handling.

For design studios aiming to cut their environmental footprint, waste is no longer just a workshop problem—it’s a reputational and strategic concern.

Foam and CNC: Subtractive Speed with Heavy Offcuts

CNC routing with foam or model board has been a mainstay for decades. It’s fast, relatively low-cost, and allows big volumes to be shaped quickly. However, its subtractive nature means that waste is built into the process.

How CNC Works in Model-Making

A block of foam or dense polyurethane board is fixed onto the CNC bed. A router bit cuts away material layer by layer until the desired contours and building forms are revealed. The process is guided by CAD/CAM software.

Where Waste Arises

Offcuts and dust: For every piece shaped, there are chips, dust, and unused sections of board. These offcuts are rarely recyclable, especially once adhesives or paints are applied.

Over-sized stock: To ensure coverage, makers often start with larger blocks than needed, leading to excess trimming.

Revisions and re-runs: Planning models often change mid-process. If a design update arrives after milling, an entire sheet may become redundant.

Packaging and transport: Foam panels are bulky and fragile. They need protective wrapping, increasing material use for delivery.

The Environmental Impact

CNC workshops require dust extraction systems running throughout the process. These consume additional energy and rely on filters that need replacement. While foam itself is lightweight, its production is energy-intensive, and its disposal is problematic due to contamination and low recyclability.

In short, CNC’s efficiency at shaping comes at the cost of significant physical waste.

Large-Format SLA: Additive Precision with Smart Material Use

Large-format SLA 3D printing flips the equation. Instead of carving away from a block, it builds up models layer by layer using liquid photopolymer resin cured by lasers or UV light.

How SLA Works

A build platform lowers into a vat of resin. A laser selectively cures areas layer by layer until the model is complete. With modern machines capable of printing volumes of 750 × 750 × 550 mm, entire site sections can be produced in one piece.

Where SLA Saves Waste

Material efficiency: Only the model’s geometry is printed. Hollowing and lightweight lattice infill reduce resin use without sacrificing strength.

Support optimization: Clever orientation and custom supports cut down on excess material.

Part consolidation: SLA can combine multiple details into one print, avoiding the need for separate milling and gluing stages.

Reusable components: Printed tiles, façades, or street blocks can be re-painted and repurposed across projects.

Post-Processing Waste

SLA isn’t perfectly clean. Supports must be clipped, and models are rinsed in solvents like IPA. Gloves, paper towels, and used resin add up. But compared with bags of foam offcuts and bins of dust, the scale of waste is far smaller and easier to manage.

Comparing Energy and Operational Impacts

Energy Demand

CNC: Energy spikes while cutting. Dust extraction and ventilation systems run continuously. Large jobs may require several machine hours, but once cutting stops, so does consumption.

SLA: Printers consume energy steadily throughout long builds, often overnight. Post-curing also uses UV ovens. However, batch printing multiple parts on one platform can improve efficiency.

Emissions and Health

CNC workshops create fine dust particles that require protective equipment and extraction to safeguard staff health.

SLA workshops avoid airborne particulates but involve handling liquid resins, which require gloves and proper disposal.

Both methods carry environmental and health considerations, but SLA eliminates the problem of airborne foam dust—an often-overlooked hazard.

Five Ways SLA Minimizes Waste in Practice

The sustainability advantage of SLA becomes clearer when you look at specific design strategies:

Hollowing and Shelling

Solid building masses can be reduced to thin-walled shells (1.5–3 mm) with internal ribs. This slashes resin use while maintaining surface quality.Lattice Infill

Instead of solid cores, models can feature gyroid or honeycomb infill. They retain stiffness but require far less material.Smart Orientation

Tilting a building or terrain tile reduces support density, especially on detailed façades. This not only saves resin but also reduces sanding and finishing.Parametric Level of Detail

Near-field areas can carry high detail, while peripheral blocks use simplified geometry. Material is focused where it matters most for storytelling.Reusable Modules

Context buildings, streets, or terrain tiles can be re-skinned, painted, or swapped. Unlike foam offcuts, these parts don’t have to be discarded after one use.

Where Foam/CNC Still Has a Role

It’s not all or nothing. Foam and CNC still have valid applications in sustainable workflows.

Large terrain forms: For low-detail landforms, a thin foam core milled quickly may be more efficient than printing vast, simple slopes.

Speed on simple shapes: CNC can remove bulk quickly when deadlines are extremely tight.

Hybrid builds: Many studios now combine methods—milling the terrain in foam, then adding SLA-printed buildings for detail. This balances speed, cost, and material efficiency.

The key is using CNC where it’s inherently low-waste and SLA where precision and reusability matter most.

Transport and Logistics: Hidden Waste Factors

Sustainability isn’t just about the workshop. How models move also affects their footprint.

Foam/CNC models: Bulky, fragile panels require careful packing. Couriers often add layers of plastic wrap and foam sheets.

SLA models: Resin prints, especially when hollowed, are lighter and can be designed to break down into modules. This reduces packaging needs and allows for easier transport by hand luggage or compact cases.

If you’re presenting internationally, these logistics can be the difference between a dozen protective crates and a single carry-on case.

Practical Steps for Architects to Reduce Waste

Whether you use SLA, CNC, or both, your design choices can directly influence sustainability outcomes.

Share clean geometry: Provide watertight CAD exports so the model shop can hollow or split parts efficiently.

Declare sustainability goals: Add waste reduction or reusability to your project brief. This gives vendors permission to optimize.

Prioritize local production: A nearby SLA workshop cuts courier miles and packaging waste.

Specify smart finishes: Request primer-ready surfaces and modular painting rather than heavy coatings.

Design for reuse: Incorporate magnets, dowels, or interchangeable tiles so elements can live on after one project.

The Bigger Picture: From Models to Practice Sustainability

Choosing SLA over CNC doesn’t make a practice sustainable overnight. But it’s part of a larger story: reducing hidden waste in everyday workflows. Clients and planning authorities increasingly ask about environmental impacts, and physical models are a visible symbol of your approach.

By demonstrating that your presentation materials are considered, efficient, and designed with circular use in mind, you reinforce your commitment to sustainability beyond the building design itself.

Conclusion: A Balanced, Low-Waste Future

If we measure strictly by waste, large-format SLA holds a clear advantage over foam/CNC. Additive manufacturing builds only what’s needed, and smart preparation can significantly reduce resin consumption. Foam/CNC, while quick and familiar, is inherently waste-heavy due to its subtractive nature.

That doesn’t mean CNC is obsolete. For terrain and speed, it still has a role. But the sustainability case increasingly points toward hybrid approaches: milling where it’s efficient, printing where precision and reusability matter, and combining both to minimize scrap.

Ultimately, reducing waste in site models isn’t about tools alone. It’s about mindset—designing with material efficiency in mind, choosing local production, and planning for reuse. For practices serious about sustainability, the message is clear: rethink not only the buildings you design but also the way you present them.

When working in 3D design environments like Revit, Rhino, or Blender, exporting your model in the right file format can significantly impact how it performs across software, whether for 3D printing, rendering, simulation, or BIM integration. The four most common file types—STL, OBJ, FBX, and STEP—serve different purposes, and choosing the wrong one can lead to data loss, bloated files, or failed imports. Here's a detailed, intent-driven comparison of when to use each—and how to ensure your exports are watertight.

STL (Stereolithography): Best for 3D Printing

Use STL when:

You need a lightweight, triangle-based mesh.

Color and texture data are irrelevant.

Pros:

Compact file size.

Simple geometry = faster slicing.

Cons:

No support for textures, colors, or materials.

Only supports triangular meshes.

Lacks scale metadata—units must be clarified manually.

Watertight Tip:

STL exports are notorious for producing non-manifold edges. Always run a mesh repair check in tools like Netfabb, Meshmixer, or Blender’s “3D Print Toolbox” before sending to print.

OBJ (Wavefront OBJ): Best for Mesh Editing & Rendering

Use OBJ when:

You need to export models for rendering, game engines, or mesh editing.

Preserving UV maps, textures, and normals is essential.

Pros:

Retains vertex color, texture coordinates, and normals.

Compatible with many 3D graphics and animation tools.

Works well for high-fidelity visual projects.

Cons:

Larger file size than STL.

May not be supported natively by CAD or BIM software.

Doesn’t handle parametric or hierarchy data well.

Watertight Tip:

While OBJ can carry detailed surface information, it still lacks parametric intelligence. Ensure “Merge Vertices” is enabled on export to prevent hidden cracks in joined surfaces.

FBX (Filmbox): Best for Animation & Game Engines

Use FBX when:

Your model includes animation, rigging, or hierarchical scene data.

You're importing/exporting between Blender, Unity, Unreal, or 3ds Max.

Pros:

Supports full scene structure, including cameras, lights, animations.

Preserves material and texture assignments.

Industry standard for game development and VFX pipelines.

Cons:

Proprietary format (Autodesk)—interoperability can be flaky.

Can be unnecessarily complex for static models.

Export/import inconsistencies across versions.

Watertight Tip:

FBX isn’t usually used for manufacturing, but if you're converting animated assets into a mesh, ensure modifiers are applied and the final geometry is closed before export.

STEP (Standard for the Exchange of Product Data): Best for CAD & BIM

Use STEP when:

You’re exporting parametric models or BIM elements.

You need to preserve solid geometry, assembly hierarchies, and accurate units.

Pros:

Ideal for engineering workflows and manufacturing.

Maintains NURBS surfaces and part metadata.

Excellent compatibility with Revit, SolidWorks, Fusion 360, and more.

Cons:

Not suitable for high-poly meshes or animation.

File size can become large with complex assemblies.

Limited support in artistic tools like Blender.

Watertight Tip:

STEP files are typically solid bodies by definition. However, export settings matter—use BREP export and confirm that faces form a closed shell in your CAD software.

Bonus: How to Check if a Model is “Watertight”

Regardless of file format, watertightness means that your model has:

No open edges or holes.

Proper face orientation (normals facing outward).

All meshes merged and non-manifold edges removed.

Tools for watertight checks:

Blender: Enable the “3D Print Toolbox” and use “Check All”.

Netfabb: Offers automated mesh repair and gap detection.

Rhino: Use “Check” or “ShowEdges” to find naked edges.

Revit: Though not mesh-based, exporting solids with proper BREP options can ensure closed geometry.

Final Thoughts

Choosing between STL, OBJ, FBX, and STEP isn’t just about file compatibility—it’s about aligning your end-use intent with the strengths of each format. Whether you're exporting for fabrication, rendering, animation, or coordination, the correct format—and a watertight mesh—will save you hours of frustration.

Semantically aligned exports not only enhance downstream workflows but also future-proof your assets for interoperability and reuse. And in a world where digital assets flow between industries, exporting clean, watertight, and well-structured models is a skill worth mastering.

3D printing turns a digital idea into a real object — one very thin layer at a time. For architectural models and high‑detail parts, SLA (stereolithography) is often the best choice: it produces smooth surfaces and fine detail that make models look professional right out of the printer.

This guide is written for people who want to use a professional 3D printing service (not desktop filament machines). It explains the SLA workflow, the file types we accept, materials we commonly use, and what to expect for pricing and delivery.

1. What exactly is 3D printing?

Additive manufacturing: the machine builds parts by adding thin layers of material instead of cutting away.

Digital to physical: printers follow a 3D file (your model) and reproduce it layer by layer.

SLA in short: a liquid photopolymer resin is selectively cured (hardened) by a laser or LCD projector to form each layer — excellent for high resolution and smooth finishes.

2. Five simple steps from idea to SLA part

This section focuses on the SLA workflow used by professional services.

1. Create or export a model

Architects commonly use Revit, Rhino, 3ds Max, Blender, or Fusion 360. Save/export as STL, OBJ, FBX, or STEP (FBX is widely used in architecture). Make sure geometry is watertight.

2. Prepare the file (slicing & supports)

We import your model into print‑prep software. For SLA that means orienting the part, adding supports where needed, and setting layer height and exposure parameters.

The slicer converts the model into thin slices and generates the machine instructions (often a printer-specific file). Good orientation and support strategy reduce print time and surface blemishes.

3. Machine preparation

The SLA machine uses a resin vat and a build platform. We check the vat membrane, top up the chosen resin, and calibrate the build platform to ensure accurate layers and adhesion.

4. Print — layer by layer

A laser or masked LCD cures each cross‑section of the model. The platform lifts and the next layer is cured. SLA excels at fine detail and smooth faces compared with most other technologies.

5. Post‑processing

Typical SLA post‑process: wash in solvent (e.g., IPA alternatives where required), remove support structures, and final UV post‑cure to achieve full mechanical properties. After that we sand, paint, or assemble as needed for presentation models.

3. Common materials we use (SLA-first)

Standard photopolymer resin — great surface finish for display models and concept visuals.

Engineering / Tough resins — higher impact resistance for working prototypes.

High‑temperature resins — for parts exposed to heat or for thermoforming patterns.

Castable (investment) resin — used when a part needs to be cast in metal afterward (jewellery, fixtures).

Flexible resins — for soft components or tactile models.

Ceramic‑filled / composite resins — for special textures or heavier feel.

Metal (printed & finished) — stainless steel, titanium, or aluminium via metal additive manufacturing when a structural metal part is required.

Note: We do not rely on desktop filament materials like PLA or nylon for our SLA presentation work — we focus on resins and professional materials matched to each project's needs.

4. Why choose a professional SLA printing service?

High resolution & surface quality — fine features and smooth finishes right from the printer.

Large format capability — single‑piece prints up to 750 × 750 × 650 mm on our large

SLA systems (or multipart builds assembled and finished to look seamless).

Expert file prep — we handle support placement, orientation, hollowing and wall‑thickness checks so prints succeed first time.

Confidential handling & NDAs — professional workflows for client confidentiality.

Full finishing & assembly — sanding, painting, and model assembly so your deliverable is presentation‑ready.

5. Ready to print? How it works (quick)

Upload your STL, OBJ, FBX, or STEP file.

Choose material, desired finish, and turnaround.

Get a live quote and confirm the order.

We print, finish, and deliver or make available for collection.

6. Quick FAQ (focused on SLA & architectural needs)

Q — Can I print large objects in one piece? Yes — our large SLA machines can print up to 750 × 750 × 650 mm in a single piece depending on geometry and selected resin. Larger objects can be printed in sections and seamlessly assembled and finished.

Q — How strong are SLA parts? Strength depends on the chosen resin and how the part is printed (orientation, layer height, wall thickness). Engineering resins and post‑cure greatly improve mechanical properties. For structural or load‑bearing parts, we usually recommend metal printing or SLS solutions depending on application.

Q — What file types do you accept? We accept STL, OBJ, FBX, and STEP. FBX is commonly used in architectural pipelines — include your original export so we can check materials and layers.

Q — Do you sign NDAs and protect confidential designs? Yes — we routinely handle confidential projects and can sign NDAs on request.

Q — What tolerances and finishes can you achieve? Typical SLA tolerances depend on part size and resin; we commonly achieve fine surface detail (sub‑0.1 mm features). We offer sanding, primer, paint, and assembly to presentation standards.

7. Final thoughts

For architectural models and high‑fidelity presentation pieces, SLA printing plus professional finishing gives the best combination of detail, surface finish, and visual quality. If you’d like, send an FBX or STL and we’ll check the file free of charge and give a realistic quote and lead time.

Upload your model to get an instant quote →

If you want this rewritten to match Fixie 3D's exact tone and brand voice (shorter, more formal, or more playful), or if you want the post tailored specifically for an architecture audience with added visuals, I can produce that next.

Modelmaking—whether for architecture, product design, film props, or tabletop gaming—was long dominated by subtractive processes: you started with a solid block and milled, routed, or laser-cut away everything that didn’t belong. Today, high-resolution stereolithography (SLA) printers—machines that cost hundreds of thousands of dollars and can fill an entire studio bay—have flipped that workflow on its head. They build models layer by micro-thin layer, curing liquid resin with ultraviolet light to produce objects that come off the platform smooth, intricate, and ready for paint.

This change is far more than a technical upgrade. By replacing cutters and chips with light and resin, SLA technology is altering the economics, creativity, and sustainability of modelmaking itself.

1. Subtractive Basics—The Old Guard

What is subtractive manufacturing?

CNC milling, routing, turning, water-jet cutting, and laser-cutting all fall under subtractive manufacturing: tools remove material from wood, foam, metal, or plastic blanks until the desired shape appears.

Why model-makers relied on it

Accuracy: A five-axis mill can hold tolerances down to single-digit microns.

Surface quality: Machined acrylic or aluminum leaves the tool nearly showroom-ready.

Material strength: Machined metals shrug off handling and transport.

Yet subtractive methods bring big trade-offs: high material waste, long set-ups for fixturing and tool-paths, limited internal geometry, and steep costs for complex shapes.

2. Additive Manufacturing—Why SLA Leads

How SLA Works

Instead of carving away, SLA printers project or scan UV light into a vat of photopolymer resin. The resin solidifies where illuminated, forming a razor-thin layer; the build platform then rises, and the next layer is cured on top. Industrial SLA machines extend this principle to meter-scale envelopes while holding tolerances rivaling precision machining.

Why professional studios choose SLA over FDM

Large-Format SLA vs. Bench-Top FDM – Key Advantages

Surface Finish

Large-Format SLA:

Glass-smooth finish right off the printer

Minimal sanding required

Ideal for architectural facades

Bench-Top FDM:

Visible layer lines

Heavy post-processing and sanding needed

Detail Resolution

Large-Format SLA:

Supports sub-100 µm features

Captures fine mullions, relief textures, engraved lettering

Bench-Top FDM:

Limited to 200–400 µm feature size

Small details often blur or lose definition

Build Volume

Large-Format SLA:

Build chambers up to 1500 mm long

Can print an entire 1:100 tower core in one go

Bench-Top FDM:

Limited desktop footprint

Larger or taller parts must be split and glued

Material Range

Large-Format SLA:

Compatible with rigid, clear, engineering-grade, high-temperature, and castable resins

Bench-Top FDM:

Primarily uses commodity thermoplastics like PLA, PET-G, and ABS

Up-front Cost

Large-Format SLA:

$200,000+ per machine

Justified by labor savings on machining and sanding

Bench-Top FDM:

$1,000–$5,000 per machine

Suitable mainly for rough and basic study models

Studios pay the premium because SLA combines CNC-grade precision with “print-and-paint” convenience, eliminating the layer-line headaches that make FDM a non-starter for showcase architectural work.

High-resolution architectural model of a modern skyscraper produced using SLA 3D printing technology, showcasing intricate detail and precision in modelmaking.

3. Head-to-Head: SLA vs. Subtractive Machining

Geometry Freedom

5-Axis CNC / Laser:

Limited by cutter reach and tool diameter.

Industrial SLA:

Virtually unlimited geometry freedom, including internal lattices and ducts.

Material Waste

5-Axis CNC / Laser:

50–80% of stock material is wasted as chips or dust.

Industrial SLA:

Less than 10% waste; only support structures are discarded.

Setup Time

5-Axis CNC / Laser:

Requires hours of CAM programming, tool changes, and fixturing.

Industrial SLA:

Slicing a watertight STL file takes only minutes.

Cost per Unique Part

5-Axis CNC / Laser:

Cost increases significantly with design complexity.

Industrial SLA:

Complexity has minimal to no effect on cost.

Finish Workflow

5-Axis CNC / Laser:

Requires deburring, polishing, and sometimes painting.

Industrial SLA:

Just drain supports, lightly sand, and prime—ready for finishing quickly.

4. Real-World Impact on Model-making Workflows

Architectural Models

City blocks & site massings: A 1 × 0.5 m SLA bed prints hollow shells overnight, saving kilograms of foam and days of sanding.

Façade studies: Sub-100 µm layer height captures louvers and perforations that laser-cut acrylic would shatter.

Product Design & Prototyping

Snap-fit electronics housings: Tough resins mimic ABS, letting teams test living hinges before ordering steel molds.

Optically clear lenses: Transparent resin parts come off the printer ready for polish, something FDM simply cannot do.

Film Props & Miniatures

Hero props: Armor plates and sci-fi blasters print in a single piece with embossed glyphs intact.

Stop-motion puppets: Articulated joints emerge fully integrated, reducing assembly to a push-fit.

Tabletop Gaming & Dioramas

Ultra-detailed figures: Layer lines vanish under primer; painters spend their time glazing, not sanding.

Terrain tiles: Large-format SLA means full-board pieces without seams or glue-ups.

5. Limitations & Smart Hybrid Strategies

SLA is not a silver bullet:

Resin cost & storage: Photopolymers cost more per kilogram than PLA and require sealed vats.

Post-cure fragility: Parts must be UV-cured and can warp if under- or over-exposed.

Large flat stock: CNC routers still beat printers for MDF baseboards or laser-cut glazing panes.

The smartest studios mix processes: mill a rigid MDF base on the router, print the intricate façade on SLA, laser-cut acrylic windows, and drop everything together like LEGO®. The result is crisp, stable, and labor-efficient.

6. Sustainability & Cost Calculus

Material efficiency: With supports optimized, SLA tosses only a coffee-cup-sized pile of cured rafts instead of bagfuls of chips.

Energy profile: A continuous-laser SLA vat draws less peak current than a 3 kW spindle, although build times can run long.

Budget reality: While the printer itself is a capital investment, the per-part cost is often lower than machining once sanding and assembly hours are counted—even before you factor in wasted stock.

7. Practical Tips for Moving to SLA-First Workflows

Invest in clean CAD: Watertight solids save resin and heartache.

Tune supports, not just orientation: Less contact equals less sanding.

Maintain your resin: Filter regularly; fresh resin equals crisp edges.

Finish like a pro: Use fine sanding sponges, spray filler-primer, and an airbrush to achieve a marble-smooth surface.

Iterate fearlessly: Low waste plus high detail means you can print three façade variants overnight and pick the winner in the morning.

8. Conclusion—Why SLA Sets the New Standard

Subtractive machining ushered in the precision era of model-making. Large-format SLA is ushering in the freedom era—where geometry, customization, and overnight turnaround matter more than block rigidity or spindle torque. By curing only the resin you need, SLA reduces waste, slashes sanding time, and empowers designers to prototype without compromise. Hybrid workflows will always exist, but the center of gravity has shifted decisively: for architects chasing flawless facades, for industrial designers iterating housings, and for film artists crafting impossible props, large-format SLA is the new cornerstone of modern model-making. Embrace it, integrate it, and watch your creative possibilities grow layer by perfectly smooth layer.

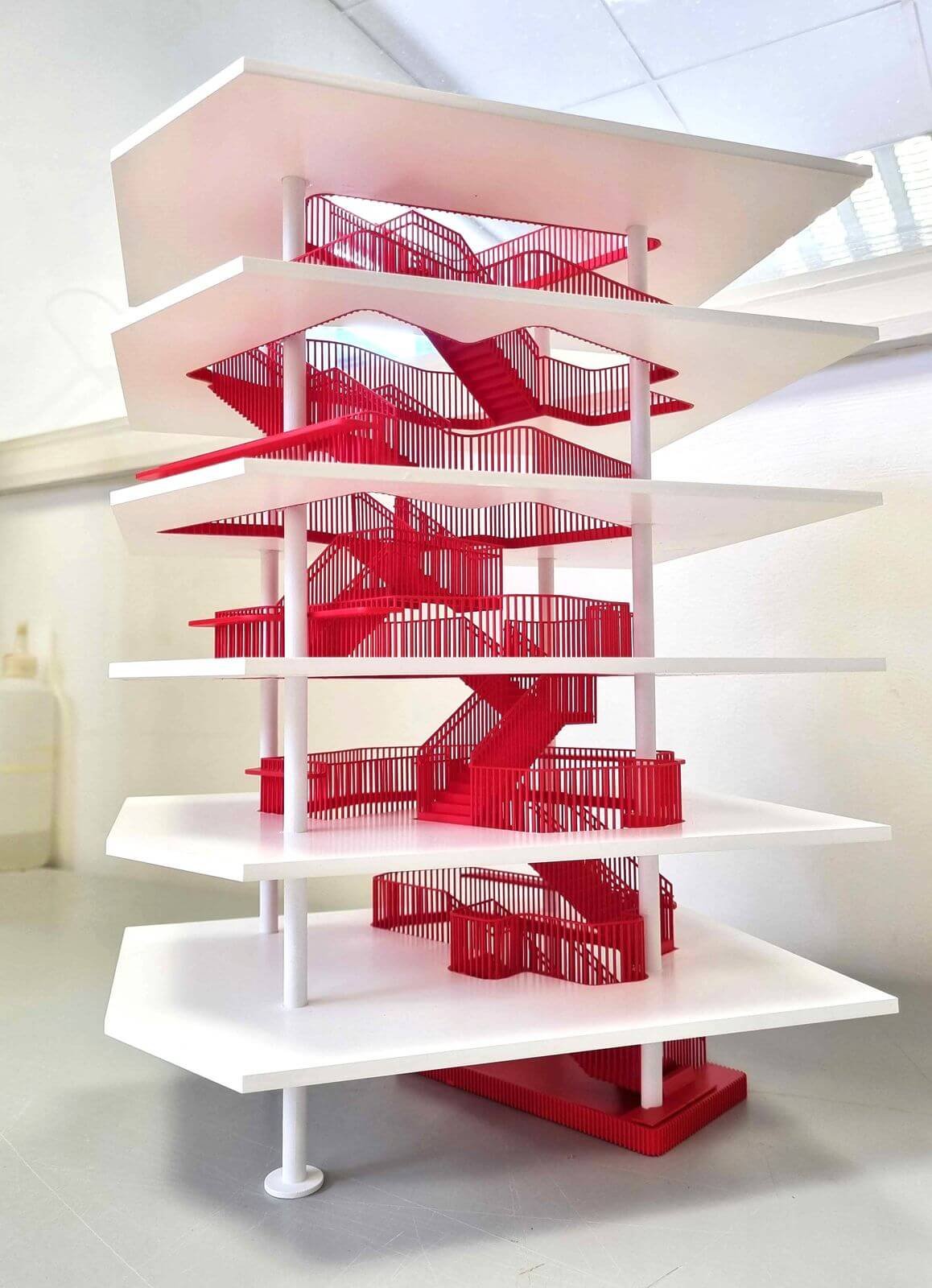

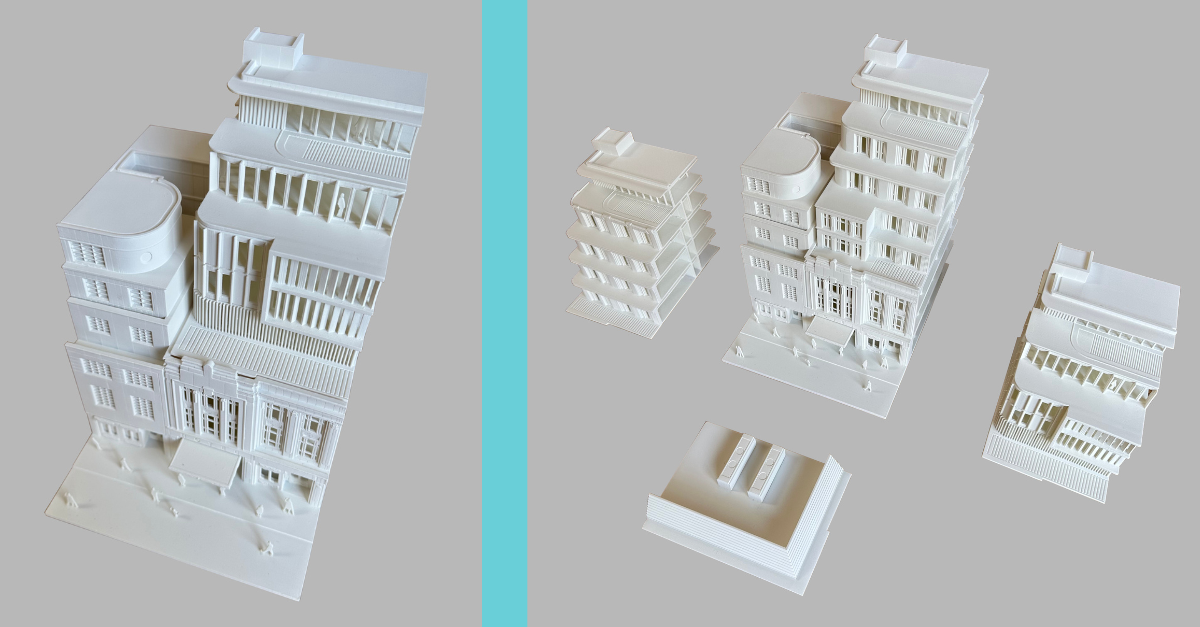

In the realm of model making, a perfect sweet spot sits where the techniques of traditional model making, laser cutting, and 3D printing converge to create a beautiful model-making experience.

This integration not only enhances the speed of production but also significantly improves cost-effectiveness by reducing material waste and labor time. Furthermore, the precision offered by laser cutting ensures clean and intricate designs, while 3D printing allows for complex shapes and fine details that would be difficult to achieve through conventional methods.

Together, these technologies elevate the overall quality of the final product, resulting in models that exhibit exceptional detail and accuracy.

For years, those of us within the 3D printing UK community have believed that 3D printing could eventually replace traditional model making. However, we have come to understand that both practices are not only distinct but also highly complementary.

While traditional model making does not rely on 3D printing, the integration of this technology significantly enhances the overall workflow. 3D printing enables the rapid production of highly detailed components with intricate geometries and complex curves that would be difficult or impossible to achieve through conventional methods.

This capability allows model makers to focus on the artistic aspects of their craft, such as refining surface textures, applying paint finishes, and perfecting details by hand. With skilled artisans working alongside advanced printing technology, the final models benefit from both precision engineering and expert craftsmanship, resulting in an impressive combination of functionality and aesthetic appeal.

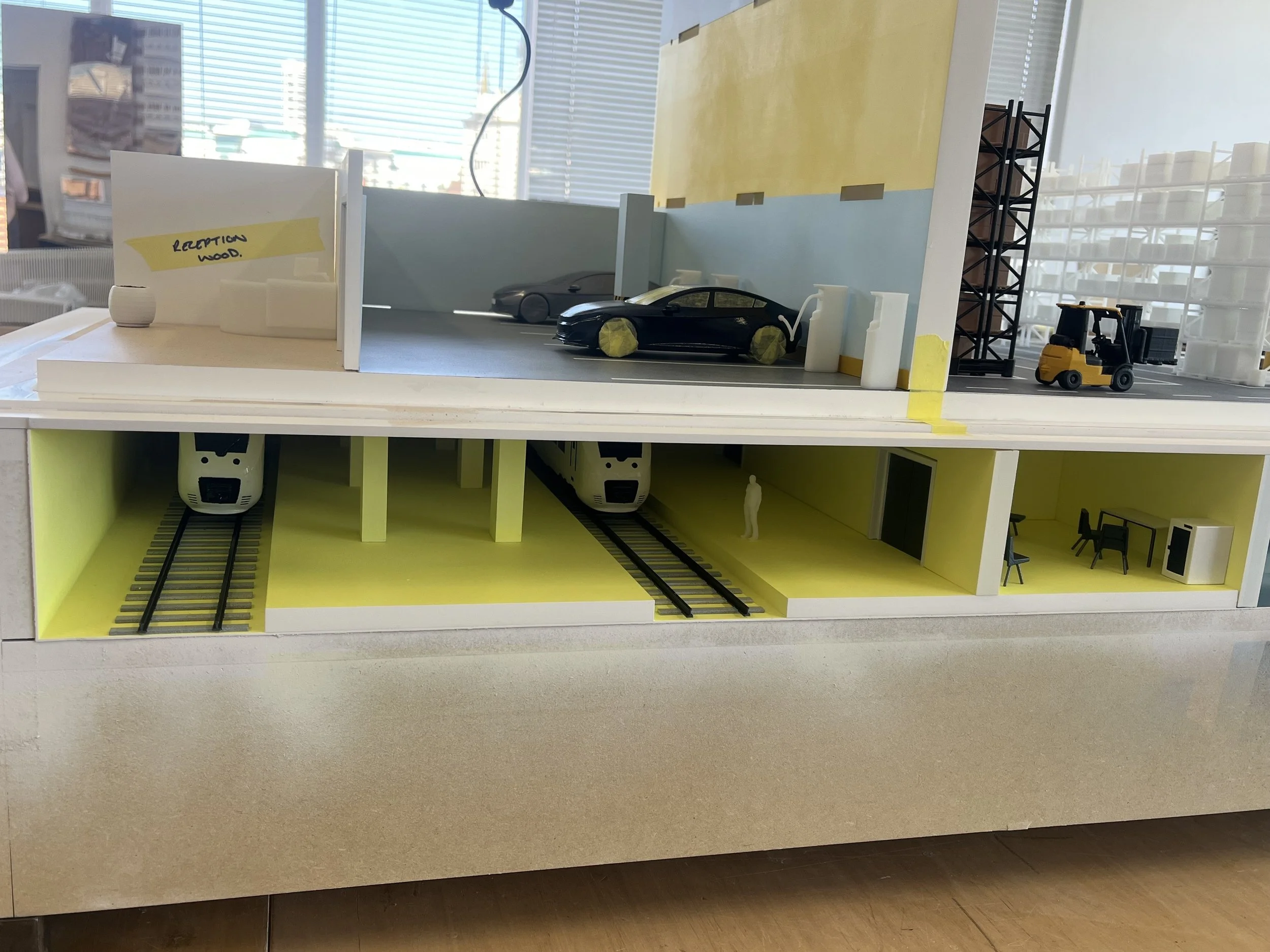

Here is an impressive example of a project we developed in collaboration with Kingel Ltd, a leading creative brand and campaign specialist, for Legrand, renowned experts in digital solutions and infrastructure development.

This project features intricate animation created using highly detailed laser technology stereolithography 3D printing. The physical structure was expertly handcrafted, incorporating high-quality materials, and was enhanced with a professional spray painting technique for a vibrant finish. Additionally, custom laser-cut glazing was incorporated to add depth and dimension, ensuring the final product was both visually striking and functional.

At Fixie, we specialise in 3D printing and understand model making, so we can combine our expertise to find the best possible method for your project. Our team understands the intricacies of breaking down models into optimal components, ensuring that each part is designed for maximum strength, detail, and ease of assembly.

Why hybrid 3D printing and traditional model making work

Architectural presentations demand models that are both accurate and attractive. Combining 3D printing and traditional model making meets this need by merging digital precision with human artistry. Modern additive manufacturing creates complex geometries that are difficult to craft by hand, while traditional modelmaking techniques bring warmth, texture and creative detailing to every piece

Advantages of 3D printing: precision, complex geometry, speed

Stereolithography (SLA) 3D printing UK offers the sharpest details and smoothest surface finish of all 3D technologies. Using a UV laser to cure liquid resin, SLA captures features as fine as 25 microns, ideal for architectural models requiring crisp edges and thin walls. This resin printer workflow allows rapid prototyping of curved façades, intricate lattice structures and free-form shapes, all directly from STL files.

Advantages of traditional craftsmanship: texture, finish, realism

Once printed, models benefit from hand finishing techniques such as sanding, spray painting, and assembly of multiple parts. Skilled model makers apply model finishing techniques to smooth seams, add textures, and enhance realism. Traditional tools like scalpels, rulers, and airbrushes bring a bespoke quality that machines alone cannot replicate

Typical workflow at Fixie 3D

Fixie 3D integrates 3D printing and traditional model making into a seamless service, tailored for London-based architects and designers.

Step 1: File Preparation and Consultation

Clients upload 3D model files (STL, OBJ or FBX) via our secure portal. Our technicians review the design, recommend the best 3D printing services and advise on resin types for durability or translucency

Step 2: SLA Printing at Scale

We print on large-format SLA machines (750 × 750 × 550 mm) capable of high-resolution output and multi-piece assemblies. This additive manufacturing stage captures complex details—from fine window mullions to organic façade elements—with exceptional accuracy

Step 3: Hand Assembly and Finishing

Our 3d modelmakers then remove support structures, sand surfaces, and apply spray paint to match project palettes. They also glue parts together and may incorporate CNC-cut wooden bases for a refined mixed-media effect.

Step 4: Quality Control and Delivery

Every model undergoes a final inspection for tolerances, paint consistency and structural stabilityWe then package the model securely for prompt delivery anywhere in the UK or internationally

Benefits for architects, designers, and model clients

By automating complex sections through 3D printing uk, we cut manual labour time and reduce errors, leading to faster prototype development and lower costs per unit. Architects can iterate designs quickly, testing form and scale without lengthy hand-crafting phases

Enhanced Visual Impact

The combination of digital precision and expert hand finishing creates models that stand out in client presentations and competitions Crisp resin prints capture every curve, while bespoke paintwork and textures evoke material qualities such as brick, timber or metal Scalability and Flexibility

From small concept models to large format competition entries, our hybrid workflow adapts to any project size Clients benefit from modular assembly and the ability to update individual components without reprinting an entire model.

Q: Why combine 3D printing and traditional model making?

A: Combining 3D printing’s precision with traditional craftsmanship’s finishing delivers highly detailed, realistic models efficiently.

Q: What 3D file formats are accepted for hybrid model making?

A: STL, OBJ, and FBX are typically accepted for the 3D printing stage. Fixie - Architects' AssistantQ: What is the maximum build size for large-format printing at Fixie 3D?

A: Fixie 3D’s large-format SLA build volume is 750 × 750 × 550 mm. Fixie - Architects' AssistantQ: What types of finishing can be done after printing?

A: Post-processing can include support removal, sanding, spray-painting, assembly, and mounting on CNC-cut bases for mixed-media effect. Fixie - Architects' AssistantQ: When might a pure traditional model or pure 3D print be preferable?

A: Pure traditional suits simple geometries needing texture/material realism; pure 3D print suits rapid prototyping with minimal finishing — hybrid suits most detailed architectural models.

Conclusion

The best approach truly combines 3D printing and traditional model making. At Fixie 3D in London, our SLA technology delivers the finest details and complex curves, while our model makers apply their creativity to handcraft the rest. This synergy accelerates prototype development, enhances visual impact, and offers a cost-effective, scalable solution for architects and designers.

The architectural industry has undergone significant changes in recent years, and one of the most transformative shifts has been the widespread adoption of 3D design software. In fact, 72% of architects use this software, reflecting how integral it has become to the design process. This shift not only makes the design process more efficient but also allows architects to visualise their ideas in more detail and realism than ever before. But the benefits of 3D design software go beyond just the architects themselves. Its growing use has led to a deeper understanding and adoption of 3D file formats by model makers, creating new opportunities and challenges for everyone involved in the architectural design and model-making process.

At Fixie 3D, based in London, we understand how critical it is for architects to create highly detailed and accurate models. The rise of 3D design software has revolutionised the way architects approach their work, enabling them to produce intricate models that were previously impossible or time-consuming to create. This technological leap has had a ripple effect, particularly in the world of model-making, where precision and scalability are paramount.

How 3D Design Software is Transforming Architecture

Before the advent of advanced 3D design software, architects relied heavily on traditional methods of drafting and physical models to communicate their designs. These methods, while effective, were often time-consuming and limited in terms of visual representation. Today, 3D design software such as AutoCAD, Rhino, and SketchUp enables architects to create digital representations of their designs that are not only more accurate but also allow for greater flexibility and iteration.

3D design programs provide architects with the tools to manipulate their models in real-time, testing various design elements and making adjustments as needed. This flexibility speeds up the design process and allows for the exploration of different ideas without the need for multiple iterations of physical models. Furthermore, these software tools offer advanced features like 3D rendering, which brings designs to life by adding textures, lighting, and shadows, giving architects a clearer picture of how their projects will look in the real world.

The Role of 3D File Formats in Model Making

As architects embrace 3D design software, they often need to collaborate with model makers to turn their digital designs into tangible, physical models. Here is where 3D file formats become crucial. The most common file formats used in architectural model making are STL, OBJ, and FBX, each offering different advantages depending on the needs of the project.

STL (Stereolithography) is one of the most widely used formats for 3D printing, as it defines the geometry of a 3D object without any colour or texture information. This format is perfect for producing detailed models that need to be printed using advanced 3D printing technologies, such as the ones we use at Fixie 3D. For more complex models that require textures or colours, OBJ and FBX file formats are preferred, as they support more detailed information about the surface of the object.

The adoption of 3D file formats by model makers has opened up a world of possibilities for architects. Where physical models once had to be painstakingly crafted by hand, 3D printing uk and other digital manufacturing methods now allow for quick, accurate, and highly detailed prototypes. This not only saves time and costs but also enables architects to refine their designs with greater ease.

A Closer Look at 3D Printing in Architecture

3D printing has become an indispensable tool for architects and model makers. It allows them to turn complex 3D printing models created with design software into physical prototypes with high precision. At Fixie 3D, we specialise in producing high-quality architectural models using 3D printing, offering services that include everything from creating client presentation models to design refinement and competition models.

By using 3D design software as the starting point, architects can create models that are ready for 3D printing service with minimal adjustments. The process of translating digital files into physical models is more seamless than ever, thanks to advancements in both design software and 3D printing technologies. The ability to quickly produce accurate models means architects can make design changes and test new ideas without the limitations of traditional model-making techniques.

The Future of 3D Design Software in Architecture

As 3D design software continues to evolve, its role in the architectural industry is only going to expand. The next frontier is the integration of augmented reality (AR) and virtual reality (VR) into the design process, which will further enhance how architects visualise and interact with their creations. These technologies, combined with 3D design software, will provide architects with even more powerful tools to communicate their ideas and collaborate with clients, engineers, and other stakeholders.

For model makers, this means that staying up to date with the latest 3D file formats and printing technologies will be essential. As more architects turn to 3D design programs, the need for model makers to understand these digital files will only grow. It is important for model makers to embrace the shift towards digital manufacturing, as the demand for high-quality, detailed 3D printed models continues to rise.

Conclusion

The increased use of 3D design software among architects has undoubtedly transformed the architectural industry. It has not only made the design process more efficient and effective but has also led to greater collaboration with model makers. The adoption of 3D file formats, such as STL, OBJ, and FBX, has facilitated the creation of highly detailed and accurate models, and technologies like 3D printing have made it easier than ever to turn digital designs into physical objects. At Fixie 3D which is one of best companies in 3d printing, we are proud to be part of this exciting transformation, helping architects and model makers bring their visions to life with precision and craftsmanship.

By embracing 3D design software and its associated file formats, architects and model makers are unlocking new levels of creativity and efficiency. As this trend continues to grow, the possibilities for the future of architecture are truly limitless.

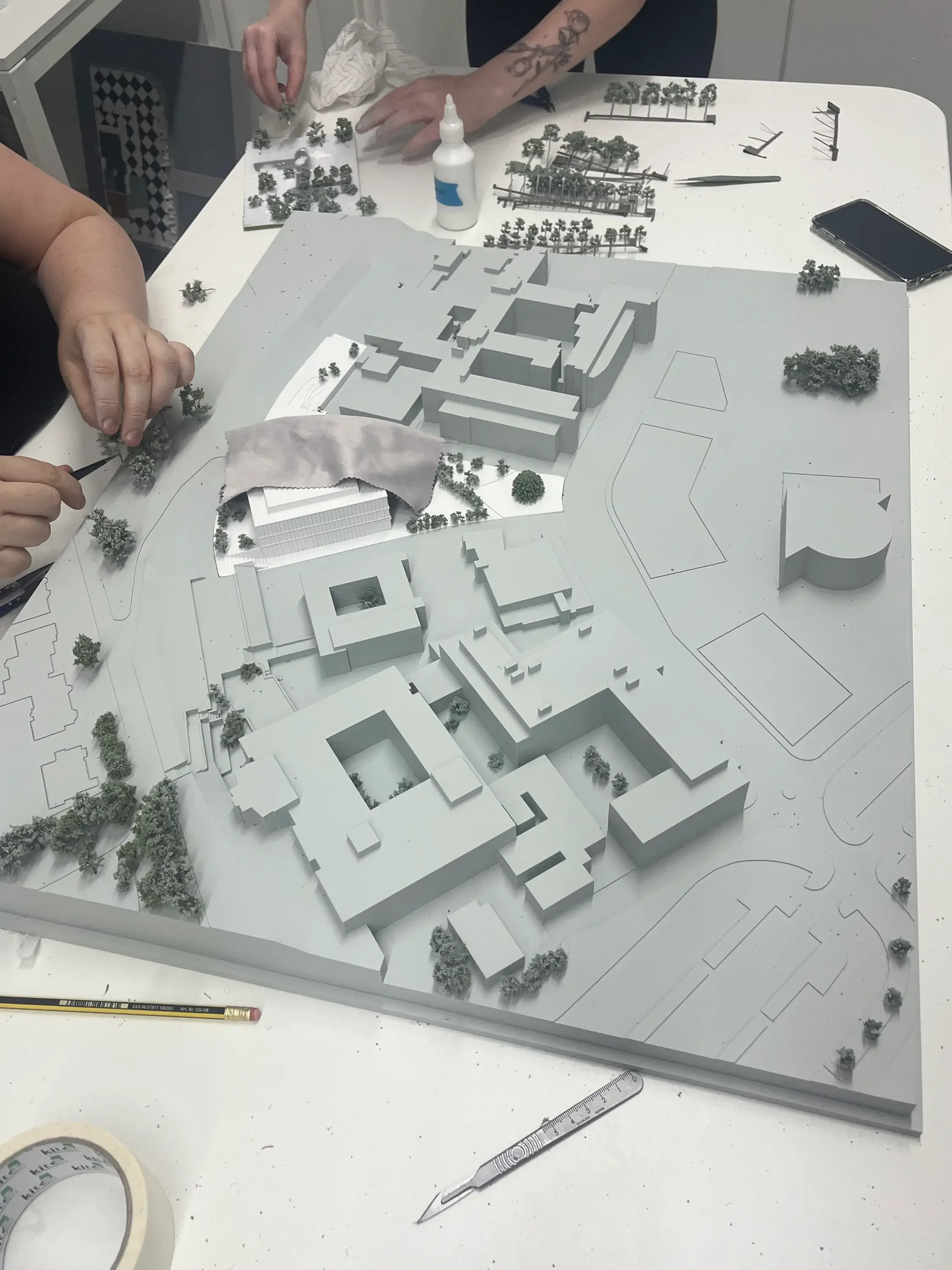

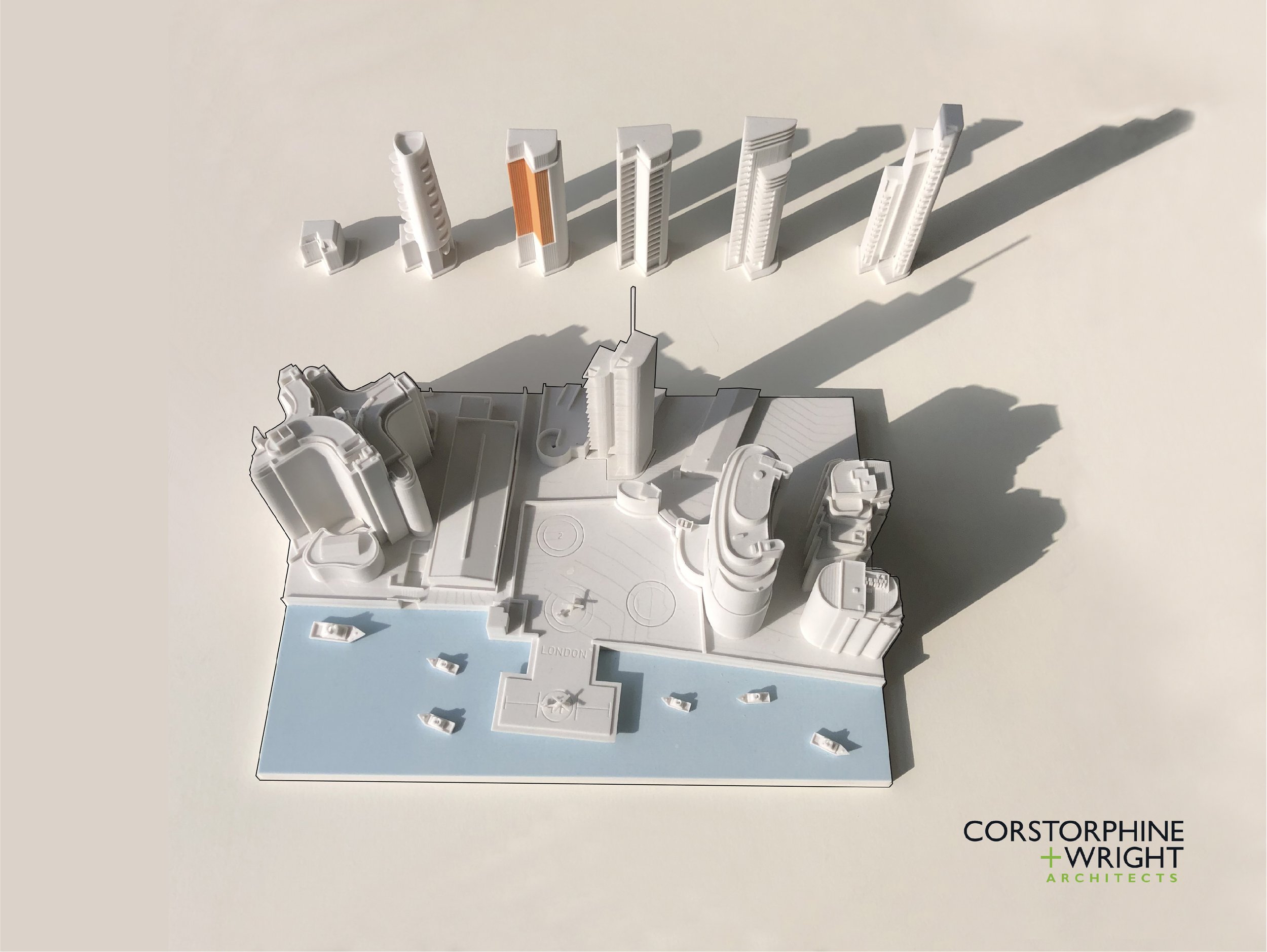

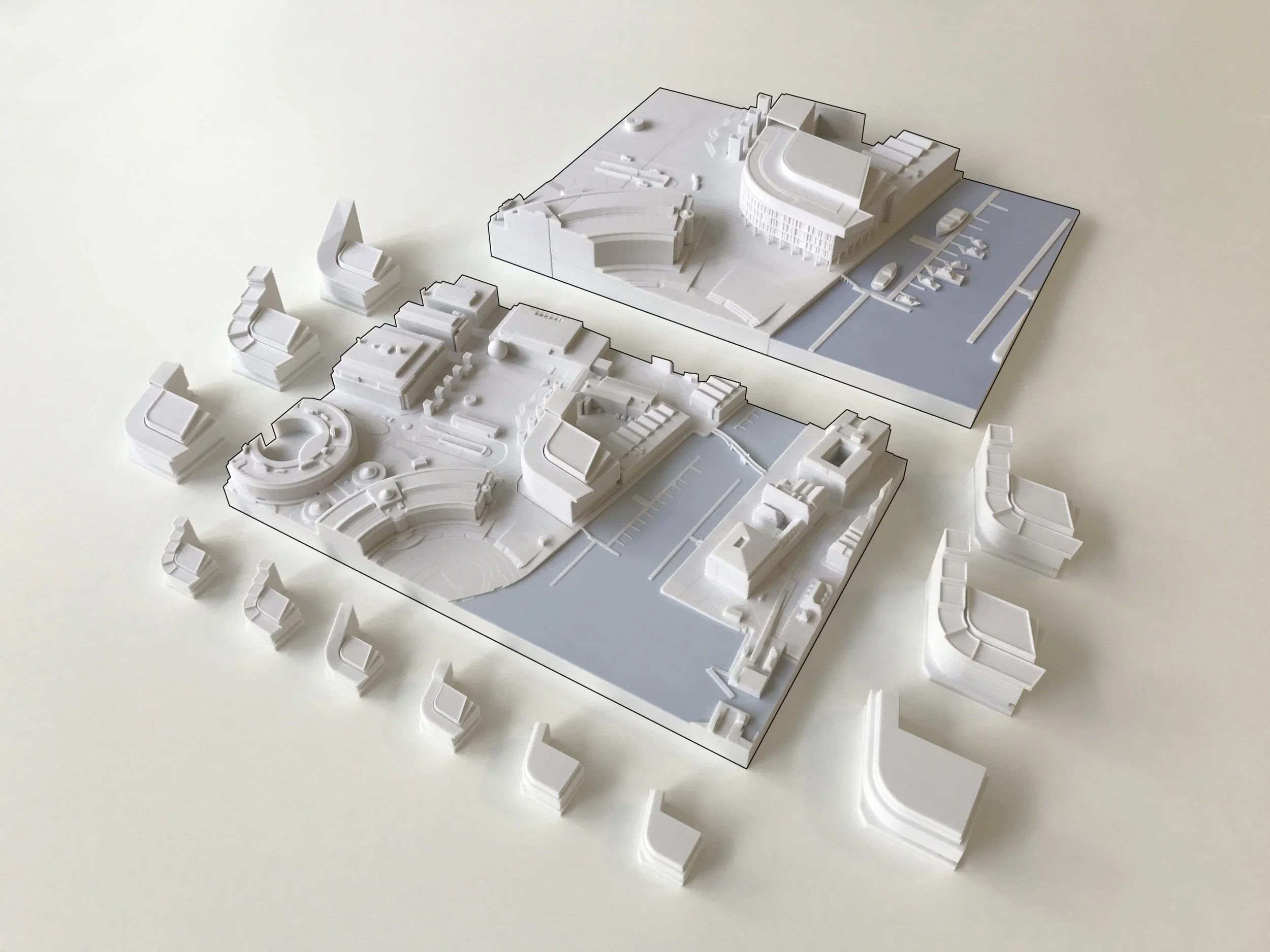

Model and design by Corstorphine + Wright

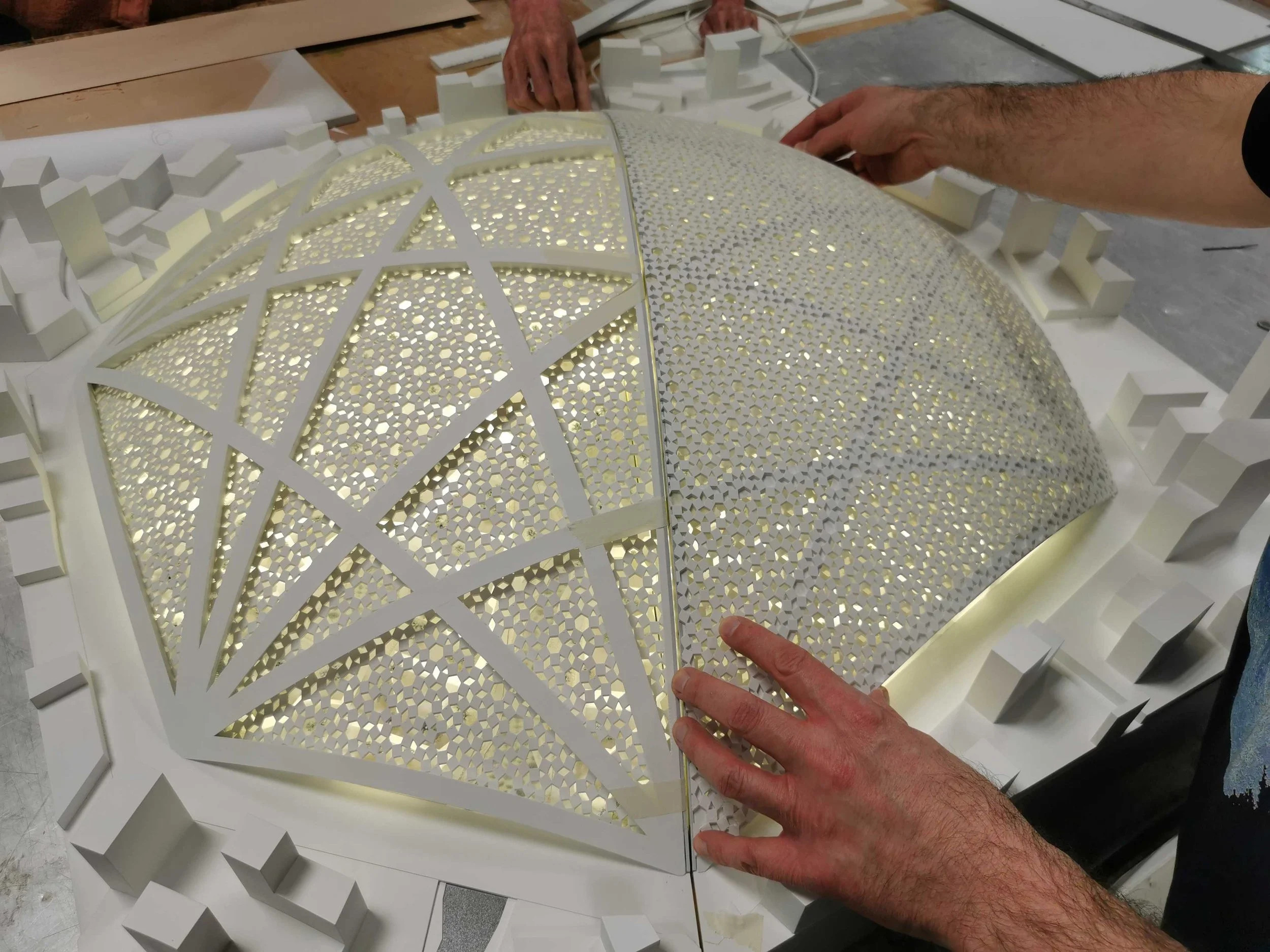

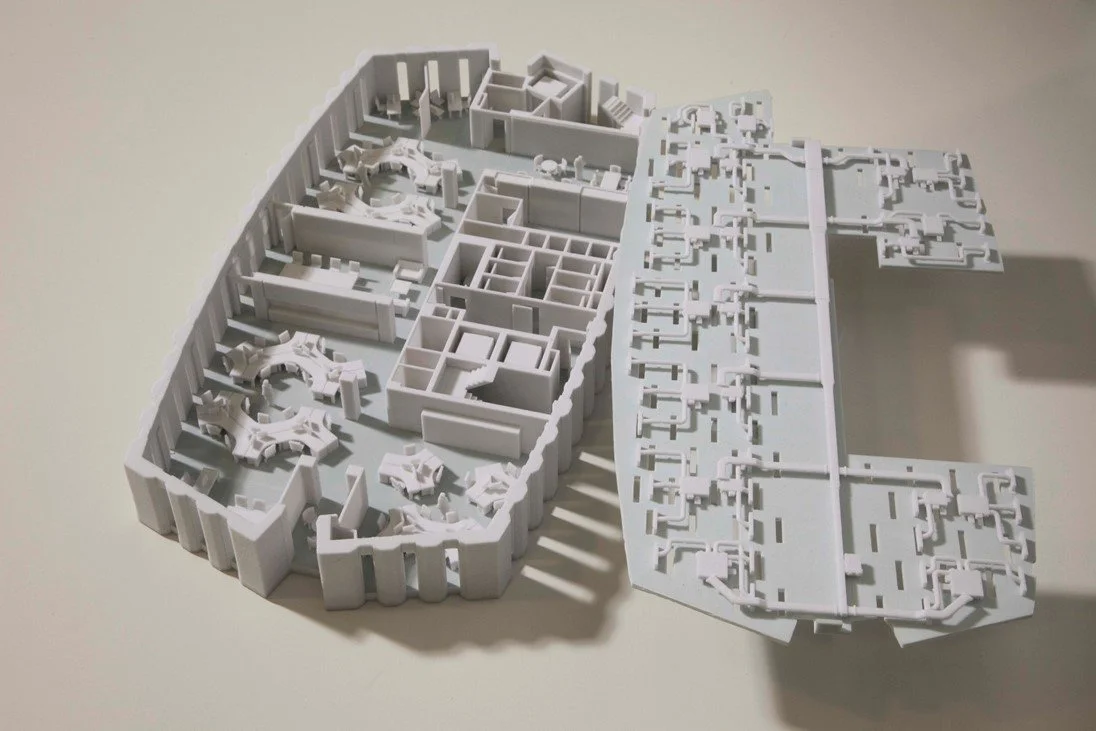

One of the most innovative contributions of 3D printing to the architectural sector is the ability to create precise context models directly from 3D aerial data.

By removing the area designated for the proposed building development, you essentially create a plug model. This approach enables the architect to design numerous iterations, providing the client with a wider range of options to choose from.

Once the client has selected their preferred design, the true advantage of the plug model becomes evident. As the development process advances, the architect is only required to reprint specific design iterations rather than the whole context of the project. This not only streamlines the workflow but also allows for quicker feedback and adjustments, as changes can be made efficiently without disrupting the entire design framework. This modular approach significantly enhances flexibility and reduces both time and resources during the development phase.

At Fixie 3D, we specialise in the meticulous file preparation of aerial 3D data, tailored specifically for architects' proposed developments. Our process ensures that all files are digitally airtight, with no gaps or errors, and that they are appropriately robust to withstand the rigors of 3D printing. Additionally, we meticulously verify that all components fit together snugly, guaranteeing optimal precision and structural integrity in the final 3d printing models.

Our technology of choice is high-end stereolithography, renowned for its exceptional smooth finish that creates an ideal surface for spray painting. This method allows for intricate designs with laser-precise details, ensuring each layer is accurately rendered for maximum clarity and precision. The result is a product that not only meets aesthetic standards but also exhibits superior quality.

Plug model of One of the most innovative contributions of 3D printing uk to the architectural sector is the ability to create precise context models directly from 3D aerial data.

By removing the area designated for the proposed building development, you essentially create a plug model. This approach enables the architect to design numerous iterations, providing the client with a wider range of options to choose from. Circus

In the world of architecture, physical models play a crucial role in visualising and communicating design ideas. Over the years, the tools used for architectural model making have evolved dramatically. Today, 3D printing has emerged as a powerful tool that has transformed the model-making process, much like laser cutters did in the past. At Fixie 3D in London, we see how these technologies bring designs to life in a way that is both efficient and remarkably detailed.

The Evolution of 3D Printers in Architectural Model Making

Traditional methods of creating architectural scale models involved a lot of manual work, from hand-cutting materials to painstaking assembly. With the advent of advanced 3D printing for architecture, the process has become much simpler and more precise. Modern 3D printers are now capable of producing high-quality design models with excellent detail, which are essential for architectural visualisation.

At Fixie 3D, our expertise in 3D printed architectural models means that we can deliver detailed architectural models that accurately represent every aspect of your design. Our laser stereolithography (SLA) 3D printers capture even the finest details, ensuring that every line and texture is reproduced with precision. This shift in technology has allowed for faster prototyping and more reliable custom model fabrication, giving architects the ability to iterate their designs quickly and efficiently.

How Laser Cutters Changed the Model Making Process

Before 3D printing took centre stage, laser cutters revolutionised the way model makers produced architectural models. Laser cutters enabled precision cutting of materials like wood, acrylic, and cardboard, which paved the way for creating architectural mock-ups and physical model making with improved accuracy. This technology made it easier to produce scale design models that were both detailed and aesthetically pleasing.

Laser cutting reduced the time required for building replicas of architectural designs. Model makers could now produce precise components that fit together seamlessly, which was a significant improvement over traditional hand-crafted methods. The integration of laser cutters in architectural model making also allowed for rapid prototyping architecture, enabling quick adjustments to design details and helping architects visualise changes in real time.

The Combined Benefits for Architects

Both 3D printing and laser cutting offer unique advantages that have redefined architectural model making. While laser cutters excel in creating crisp, flat components for assembly, 3D printers provide the capability to create complex, three-dimensional structures in a single process. This combination means that modern model making services can deliver both simplicity and complexity, meeting a wide range of design requirements.

For architects seeking high-quality design models, the benefits include:

Enhanced Detail: Advanced SLA 3D printing ensures that every intricate detail is captured, making it easier for clients to understand the design.

Speed and Efficiency: Both 3D printing for architecture and laser cutting have significantly reduced production time, enabling faster turnaround on projects.

Customisation: With custom architectural models, architects have the flexibility to experiment with different materials and finishes, achieving a look that perfectly matches their vision.

Precision: Whether through 3D printed architectural models or laser-cut components, the precision offered by these modern techniques results in architectural presentation models that are both robust and visually appealing.

A Closer Look at the Modern Process

The modern process of architectural model making now involves several integrated steps that make the creation of detailed architectural models more accessible and reliable:

Digital Design & File Optimisation:

Architects start with CAD or BIM files that are optimised for both 3D printing and laser cutting. This step ensures that every aspect of the model is feasible for production. The file preparation process is crucial in ensuring that the final architectural mock-ups accurately reflect the design intent.Rapid Prototyping:

With 3D printing for architecture, rapid prototyping becomes a straightforward process. Architects can quickly produce prototype architecture models to test ideas, make modifications, and refine the design before committing to the final version.Production & Finishing:

Once the digital file is ready, advanced 3D printers and laser cutters come into play. The 3D printed architectural models are produced using high-quality materials that ensure both durability and visual appeal. For projects that require a more traditional touch, laser-cut components are assembled to create a cohesive model. Finishing touches, such as spray painting or manual assembly, help create a polished, professional presentation model.Final Presentation:

The end result is a detailed architectural model that is perfect for client presentations, competitions, and internal design reviews. The use of professional model making services guarantees that every project meets the high standards expected in the industry.

Fixie 3D: Leading the Way in Architectural Model Making

Based in London, Fixie 3D has been at the forefront of the architectural model making revolution. Our commitment to quality and innovation means that we are constantly updating our technology to meet the evolving needs of architects. Whether you require 3D printed architectural models for a quick client presentation or a full-scale model for a major competition, our team is ready to assist with expert guidance and reliable service.

We understand that architectural model making is not just about producing a physical replica of a design; it’s about capturing the essence of an idea and conveying it in a way that is both engaging and accurate. Our combination of advanced 3D printing and precise laser cutting technologies allows us to offer professional model making services that truly make a difference in the architectural design process.

Conclusion

The evolution of 3D printers has had a profound impact on architectural model making, much like the earlier transformation brought by laser cutters. These technological advancements have streamlined the process, enhanced precision, and opened up new creative possibilities for architects. At Fixie 3D, we harness these modern tools to deliver detailed, high-quality design models that help bring architectural visions to life.

By embracing these innovations, architects now have access to a faster, more accurate, and highly customisable method of creating architectural scale models. Whether you are a seasoned professional or a newcomer to the field, the integration of 3D printing and laser cutting into the model-making process offers a powerful solution for all your design needs.

3D printed models used to be expensive and technically challenging to prepare, but not anymore! With better methods incorporating traditional modelmaking and more know-how around digital file prep, 3D printing service for architects is now much more accessible, affordable, and of a better quality

Project by MossessianArchitects

Early design models are now becoming a trend! These models are usually no bigger than A3 size, so they're easy to carry around – you can even take them as hand luggage!

This means it's super easy to show off your designs to clients and collaborators wherever you are. This whole speedy process has totally changed the design industry, making it faster to try out new ideas, communicate better, and get designs approved quicker.

Project by: Mossessian Architecture

Over 70% of architects are already using BIM technology, which allows for seamless integration with 3D printing. Specialists can prepare your STL or FBX files for printing by thickening elements and closing open spaces, all while maintaining accuracy.

Utilise a high-resolution 3D printer (such as a stereolithography printer) to fabricate the resin model. This will ensure a smooth and detailed appearance. Subsequently, apply spray paint and additional details to enhance its realism.

Project by Mossessian Architecture / 3D printed Fixie

Mossossian Architecture was tasked with creating a small-scale model for an international competition under a tight deadline. The model needed to be compact enough to fit in a carry-on bag for air travel, making 3D printing the ideal solution for this project with its beautifully designed curves. Our team of 3d modelmaker added finishing touches, such as vegetation and perspex for the pools.

Welcome to a behind-the-scenes glimpse into the fascinating world of architectural model making, a cornerstone of our design process and a bridge between abstract ideas and concrete realities.

The architect Paul Treacy shares his experiences and reflections on the pivotal role that 3D architectural models have played throughout his career, starting from his formative years at Terry Farrell and Partners to the current collaborations with the innovative team at Fixie

3D Design massing and Concept study for Waterfront Place - Bristol – Copyright – Paul Treacy ARB RIBA – Design Director Trident

As an Architect I have the great privilege of working with some very talented people and some amazing architectural firms through my career. One of the firms I worked with early in my career was Terry Farrell and Partners. Every project and design process was supported with an in-house model making process and the inevitable constant of “get Martin Giddons in” as the firm engaged with external model makers at 3DD to provide 3D models of all projects. This I fondly remember as the ‘glory days’ of UK hand model making and as I worked with some inspired and passionate people, across the breadth of London, delivering beautifully crafted architectural hand made models.