Choosing Between SLA and FDM for Architectural 3D Printing — Pros and Cons

Introduction: The Foundation of Every Architectural Print

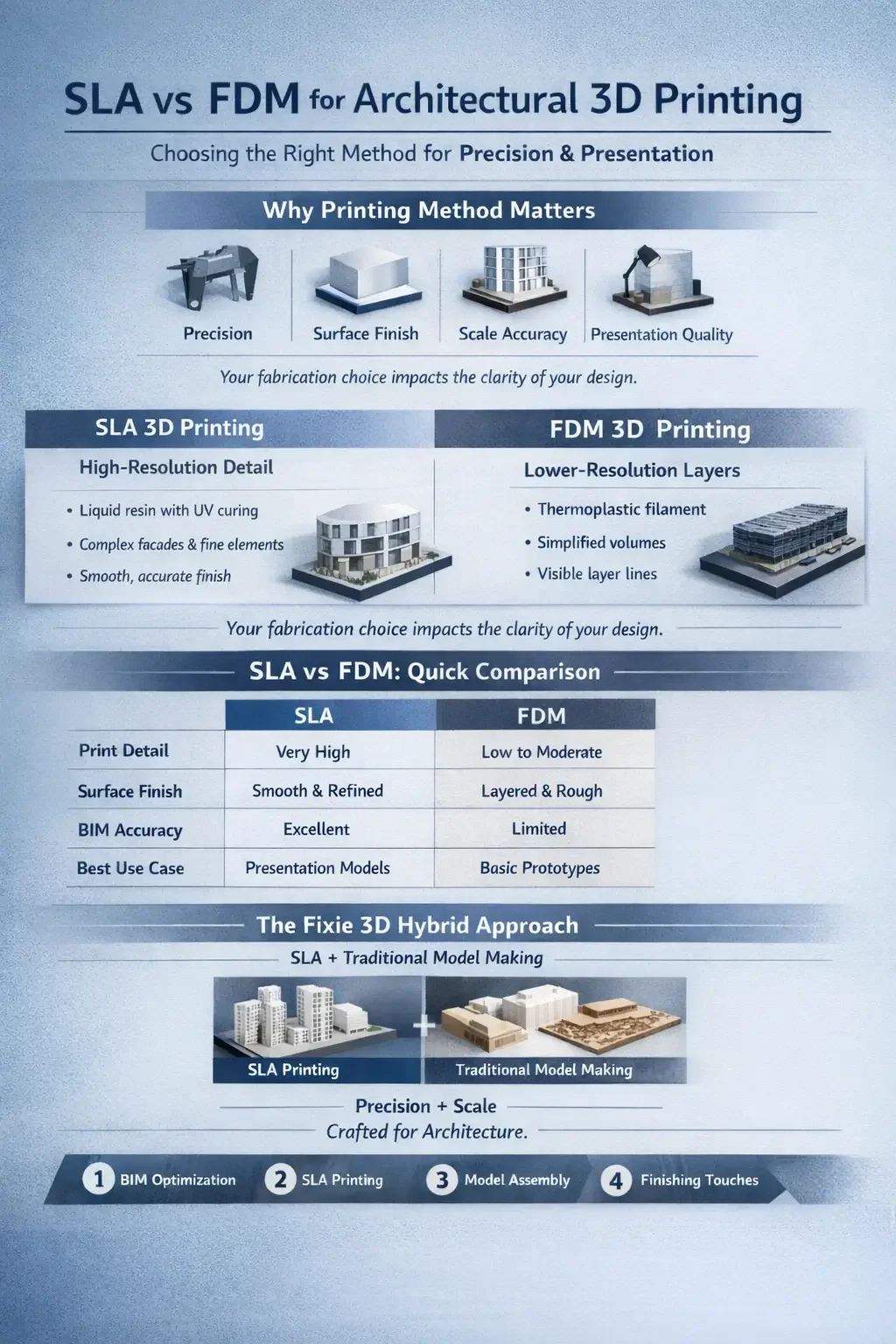

When it comes to architectural model making, precision and presentation are everything.

Whether you’re producing a conceptual massing model or a high-detail BIM-based prototype, the fabrication approach you choose will directly impact the accuracy, surface finish, and overall quality of the final model.

While SLA and FDM are often discussed together in architectural 3D printing, it’s important to understand how these technologies are referenced within professional model making workflows — and how traditional model making techniques are used alongside high-resolution printing.

At Fixie 3D, we specialise in combining SLA 3D printing with traditional architectural model making to deliver scalable, presentation-quality models without compromising detail or finish.

Understanding the Two Technologies

Before comparing approaches, it’s essential to understand how these two methods work.

SLA (Stereolithography)

SLA uses liquid resin cured by a UV laser to build highly detailed models layer by layer. It is known for smooth surfaces, fine resolution, and excellent accuracy.

At Fixie 3D, SLA printing is used for complex facades, interior elements, and scaled architectural components derived directly from BIM data.

FDM (Fused Deposition Modeling)

FDM extrudes thermoplastic filament layer by layer to form solid objects. While it is often referenced in discussions around rapid or simplified prototyping, it typically produces visible layer lines and lower surface resolution.

For professional architectural presentation models, surface quality and fine detail are critical considerations.

SLA 3D Printing for Architecture: Advantages and Limitations

Advantages

Unmatched Detail and Precision

SLA reproduces fine architectural geometries accurately, making it suitable for intricate facades, window systems, and small-scale components.Smooth Surface Finish

SLA produces clean, refined surfaces that require minimal post-processing, supporting high-quality presentations.Material Versatility

Resin materials allow for translucent and solid elements, helping visually differentiate components within a model.BIM-to-Physical Accuracy

When printing directly from Revit, Rhino, or Archicad models, SLA preserves subtle design intent.

Limitations

Higher Cost per Printed Volume

SLA materials and post-curing processes require careful and efficient use.Smaller Build Volumes

High-resolution SLA printers are best suited to detailed components rather than large single-piece structures.Longer Production Time

Print times increase as detail and accuracy increase.

These considerations are addressed through a hybrid model making workflow.

FDM in Architectural Model Discussions: Advantages and Limitations

Commonly Referenced Advantages

Production of simplified volumes

Ability to print larger single parts at lower resolution

Limitations for Architectural Presentation Models

Lower resolution and reduced detail

Visible layer lines requiring extensive finishing

Limited material aesthetics for display-quality models

For these reasons, Fixie 3D does not use FDM printing for architectural presentation models.

SLA vs FDM: Which Is Right for Your Project?

Rather than relying on a single printing method, architectural models benefit from selecting the most appropriate fabrication approach for each component. At Fixie 3D, SLA is the core 3D printing technology, supported by traditional architectural model making to achieve presentation-quality results.

Print Detail

SLA (Stereolithography): Delivers extremely high detail, making it ideal for architectural presentation models and intricate design elements.

FDM (Fused Deposition Modeling): Produces low to moderate detail and is not suitable for fine architectural features.

Surface Finish

SLA: Produces smooth, refined surfaces that require minimal finishing.

FDM: Creates visible layer lines and typically requires extensive post-processing to improve appearance.

Material Options

SLA: Uses resin-based materials that can be translucent or rigid, allowing clear visual differentiation within architectural models.

FDM: Uses thermoplastic filaments, which are functional but limited in visual refinement.

Durability

SLA: Best suited for display and presentation models where visual quality is critical.

FDM: Structurally robust but visually limited for professional presentation use.

Build Volume

SLA: Optimised for smaller components where high detail and precision are required.

FDM: Capable of producing larger single-piece prints, often at lower resolution.

Best Use Case

SLA: Detailed architectural elements and presentation-quality models derived from BIM data.

FDM: Simplified prototyping and early-stage design discussions.

Combining Both: The Fixie 3D Hybrid Approach

Many architectural models require both precision and scalability.

Instead of combining multiple printing technologies, Fixie 3D uses a hybrid approach that combines SLA 3D printing with traditional architectural model making techniques.

For example:

SLA printing is used for detailed facades, windows, and architectural features

Traditional model making is used for bases, terrain, massing, and structural components

This approach balances detail, scale, and presentation quality.

Practical Example: Printing from BIM Models

At Fixie 3D, we frequently work with Revit and Archicad files that require optimisation for physical production.

Our workflow typically includes:

Geometry cleanup and export

Detail segmentation for SLA printing and traditional fabrication

Scaling and assembly planning

Post-processing and finishing

This ensures accuracy, efficiency, and professional presentation standards.

Environmental and Sustainability Considerations

Using SLA selectively for detailed components and traditional model making for volume reduces material waste and unnecessary printing.

Fixie 3D prioritises efficient workflows that support both quality outcomes and responsible production.

Conclusion: Choosing with Purpose

Architectural models should clearly communicate design intent.

Rather than relying on lower-resolution printing methods, a hybrid approach led by high-resolution SLA printing and traditional model making delivers the best balance of detail, scale, and visual quality.

At Fixie 3D, we help architects translate BIM models into refined physical models using the right method for every element.

Ready to print your design?

Transform your BIM model into a high-detail architectural model with Fixie 3D. Upload your design and our team will guide you through the best approach for your project.